Hi-MOLD450 | Hi-MOLD560

Hi-MOLD 450 mold machining center increased rigidity and less heat generated preserves precision and repeatability in machining. This mold machining center is ideal for injection molds, die casting, plastics injection, die cutting or molding.

- Highly reliable bridge type machining center

- Highly accurate main spindles with ultra-precise angular contact bearings

- Built-in ultra-high-speed (40,000rpm) main spindle for the highest quality surface finish (Opt.)

- Built-in 5-axis table to satisfy various processing needs (Hi-MOLD560/5A)

- Hyundai WIA mold package delivers optimal processing of mold parts

- Latest SIEMENS 828D control equipped with exceptional processing software

Super Quality Mold Machining

Structure

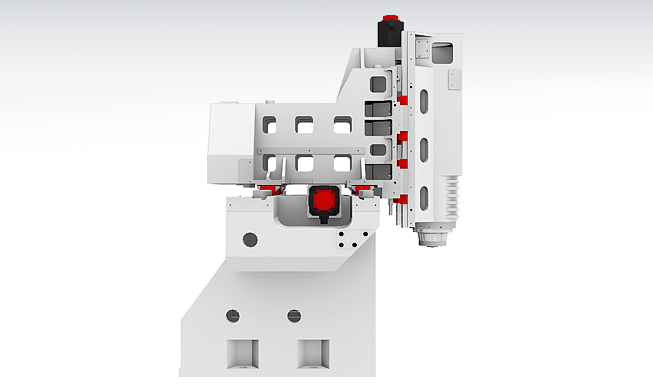

Wall Type Column Structure

Hi-MOLD450/560 are built upon a wall type frame. The biggest benefit of the bridge type machining center is the increase of rigidity and the decrease of heat generation. Hence, it retains accuracy and repeatability at the highest levels.

Ghidaje

LM Guideway

Each axis of the Hi-MOLD450/560 features slideways optimized to the model.In order to allow for flexible axis movement, ball type LM guides on the X and Y axis as well as roller type guide on the Z axis were implemented within the headstock. This makes the axis travel super fast, reducing idle time tremendously

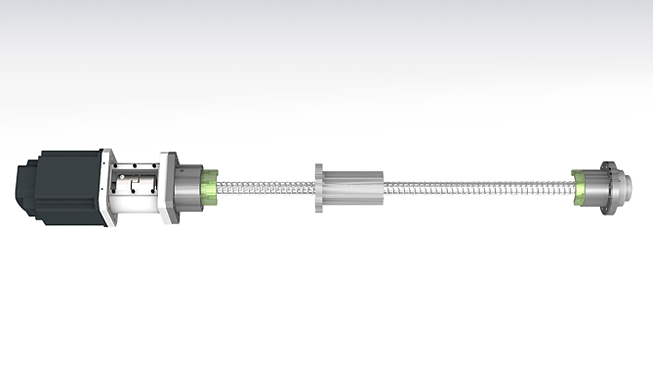

Ball Screw

All axes are driven by high precision double anchored ballscrews.

This provides outstanding positioning and repeatability with virtually no thermal growth. All ballscrews are connected directly to the servo drive motors, to eliminate backlash.

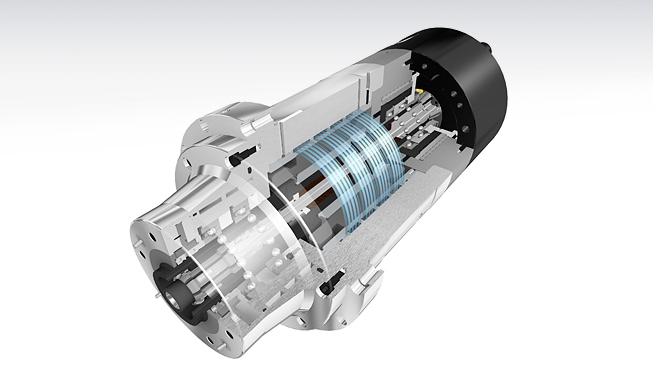

Spindle

Built-in Spindle

The built-in spindle is designed to minimize vibration and heat, as well as deliver rapid acc/ deceleration. Stable precision is maintained even under high speed and heavy duty operations.

Spindle Cooling

The spindle cooling system minimizes thermal displacement which can happen during lengthy machining operations, and offers continued accuracy based on the thermal stability.

Through Spindle Coolant

Through Spindle Coolant is exceedingly useful when drilling deep holes. It helps increase the lifetime of the tool, while decreasing cycle time.

HSK Tool Holder

The HSK spindle offers the fastest material removal rates, highest accuracy and rigidity. It guarantees stability at high speed which is excellent for mold machining.

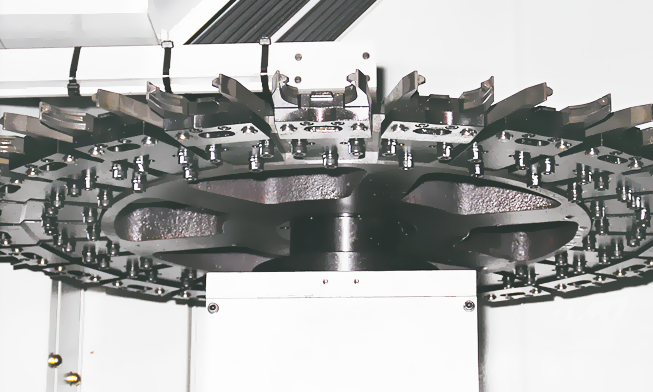

High Speed ATC

Tool Magazine

The tool magazine and machining area are completely separated by a shutter so that chip, coolant and dust particles can be blocked. This helps to maintain high precision and cleanliness

Controller

Powerful Mold Package

To enhance mold machining, the “HWM ALL-IN-ONE” is provided as a standard feature for Hi-MOLD Series machines. This ensures accurate and high quality surface finishing and contouring.

- High Speed Contouring Control (AICCⅡ)

- Development S/W

- HW-MCS (Selectable Process Conditions), HW-AFC (Adapive Feed Control)

- Main Spindle Cooling Device (8-channel) – Maintain spindle temperature (heat sensor)

- Cutting Air Blow – Cutting air blow is provided for mold machining.

- Auto Tool Measuring Device – Detects and sets tool length, and attrition

- (Graphic User Interface included)

Technical Specifications Hi-MOLD450

| Table Size [mm] | 850×500 |

| Max. Load Capacity [kg] | 300 |

| Spindle Driving Method | Built in |

| Spindle Taper | HSK-A63 |

| Spindle RPM [r/min] | 24,000 |

| Spindle Power [kW] | 33/25 |

| Spindle Torque [Nm] | 96/72.5 |

| Travel(X/Y/Z) mm | 600(+350 ATC) /450/450 |

| Rapid Feed Rate(X/Y/Z) [m/min] | 50/50/50 |

| Slide Type | LM |

| No. of Tools | 24 |

| Tool Change Time (Chip To Chip) [sec] | 5.5 |

Technical Specifications Hi-MOLD560

| Table Size [mm] | 1,250×600 |

| Max. Load Capacity [kg] | 800 |

| Spindle Driving Method | Built in |

| Spindle Taper | HSK-A63 |

| Spindle RPM [r/min] | 24,000 |

| Spindle Power [kW] | 33/25 |

| Spindle Torque [Nm] | 96/72.5 |

| Travel(X/Y/Z) mm | 1,000(+350 ATC) /560/450 |

| Rapid Feed Rate(X/Y/Z) [m/min] | 50/50/50 |

| Slide Type | LM |

| No. of Tools | 24 |

| Tool Change Time (Chip To Chip) [sec] | 5.5 |