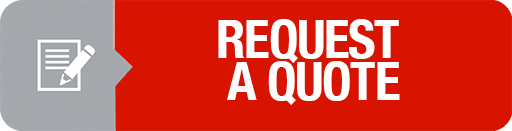

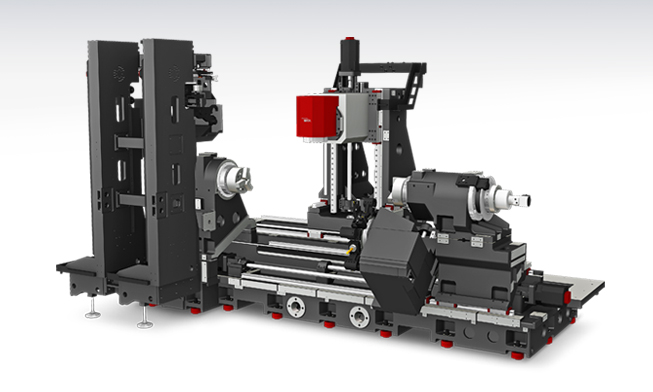

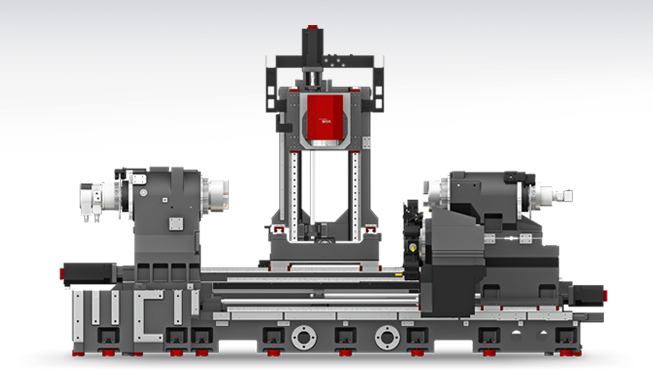

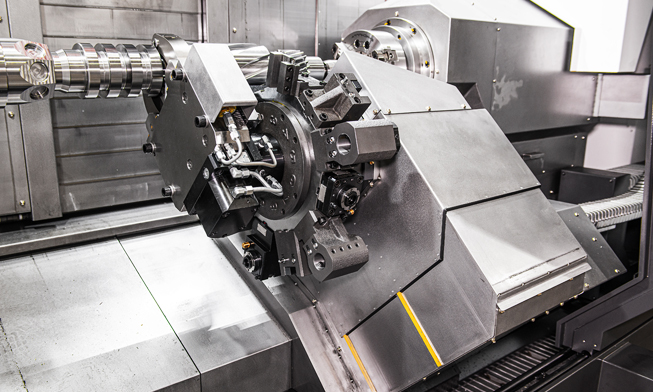

XM2600ST 9-axis Multitasking Machine

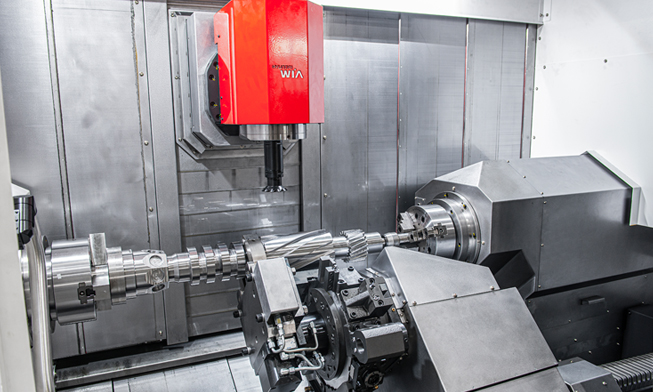

Process-intensive 9-axis Multi-tasking Machine with XM2600ST 01the Mill Head, 2 Spindle & Lower Turret

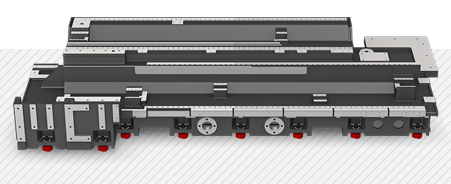

Bed structure

High Precision, High Rigidity Bed Structure

The new bed design has especially been interpreted and designed with the FEM method to minimize various factors such as thermal distortion and vibration, which could take place during machinine. Also to secure machining, XM2600ST is designed low bed structrue compared to previous model.

High-Speed Travel

Cross Type Y-axis

Wide Machining Range of Y-axis

High-Speed Roller LM Guideway

Ball Screw Nut Cooling (Z1/Y/X1 axis : Std.)

High-Precision Linear Scale

Linear scales on all axes providing high precision positioning accuracy and compensates for ball screw thermal displacement ensuring extremely precise machining. In addition, the absolute type linear scale is installed in close proximity to the ball screw of each axis.

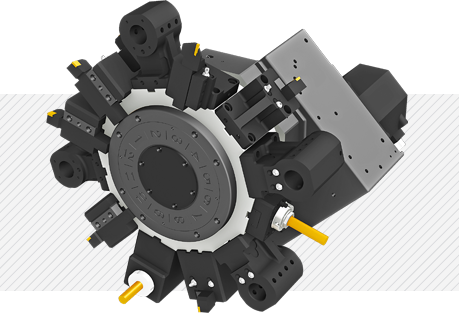

Mill Head

Milling heads for machining complex shapes

Expansion of machining range

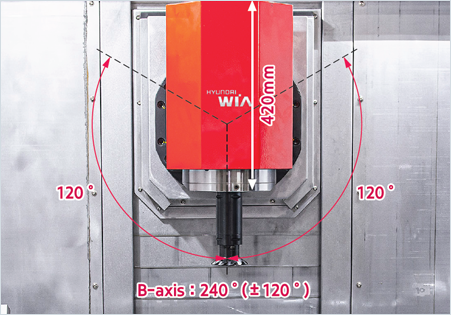

The length of the mill head has been reduced by 130mm (5.1′′) compared to the previous model to expand the machining range. <550 → 420mm (21.7′′→16.5′′)>.

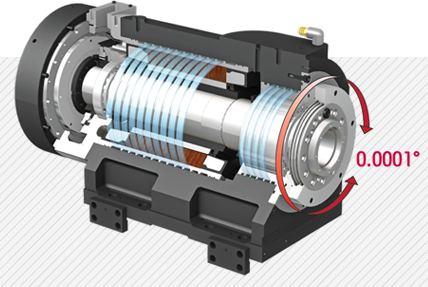

Compact Mill Head with a B-axis Operated by a High-precision DDM

The mill head is a product of combining HYUNDAI WIA’s latest technologies. The B-axis operated by DD motor method (0.0001°) to eliminate rotational backlash and spindle 1 (0.0001°) together can machine impellers, blades and other simultaneous 5-axis machining (standard application). Also, it can perfectly carry out machining of workpieces with complex shape including sloped surface, etc.

Tool Shank CAPTO-C6

CAPTO-C6, which allows double-sided circulation, is applied as a standard for maximum cutting capability.

- Ideal over load analysis

- Decreased tool change time by short taper / Excellent cutting ability

Spindle

Built-in Spindle (1st/2nd)

The 1st and 2nd spindles with a built-in motor structure can minimize the vibration and heat generated during high-speed rotation, which makes them ideal for high-precision machining. Also, Machines with a 2nd spindle can perform secondary operations with a single setup, increasing flexibility and productivity.

Spindle Oil Cooling

Turret

Turret-attached Type Rest

It guarantees machining stability by preventing tilt and shaking during machining of products such as long shafts. SLU3.2 Rest can also be applied for machining large workpieces.

Optional Mill Turret (Std. 12T Turning Turret)

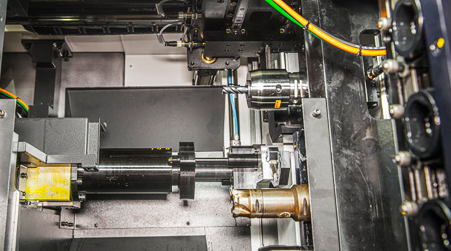

Mill Tool Holder

Machining capability has increased with the addition of straight milling head tool holder, which can machine workpieces from the side, and angular milling head tool holder, which can perform I.D. operations.

Special Tool

XM2600ST can process high value-added products using a variety of rotating tools. In particular, multi-holders for attaching variety of tools to one holder, and eccentric rotary tool for handling eccentric parts without additional axis movement, which can realize integration of process with one machine (ANGLE HEAD, GEAR HOBBING HEAD, DOUBLE TYPE HEAD).

ATC & Magazine

The installation of magazine on the front provides efficient tool change and tool setting. Magazine with chain driving method provides 40 tools as standard, and 80 tools as option.

Various Devices for User Friendly

The XM2600ST offers Ergonomic Design for Easy Operability and Maintenance.

Improved Access with Larger Front Door

The adoption of a larger front door makes crane access for cutting preparation works, such as setting up workpieces, much easier.

Highly Accessible Spindle

The spindle’s ergonomic design improves access for the chuck and makes it easier to set up workpieces.

The height from the floor to the center of the spindle has been carefully considered in order to improve the operator’s convenience when setting up work pieces.

Operation Panel

The arms for the OP box and the OP box can rotate independently, which makes operating convenient depending on the workpiece setting or worker position thus allowing the user to easily move the arms to desired location.

Video machining XM2600ST

Technical Specifications XM2600ST

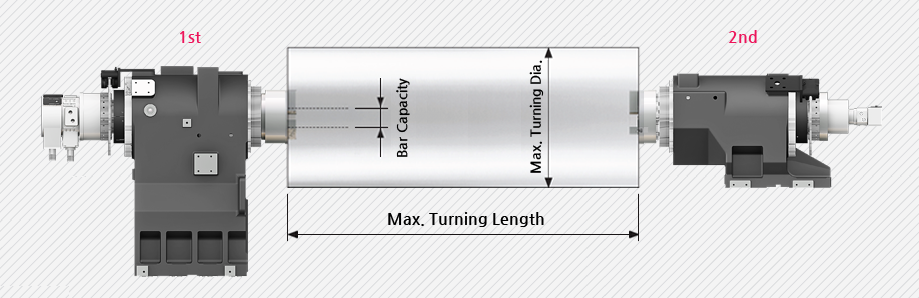

| Max Turning Dia [mm] | 660 |

| Max Turning Length [mm] | 1,540 |

| Driving Method | Built in |

| Chuck Size [inch/mm] | Main 8″/203.2 Sub 6″/152.4 |

| Spindle RPM [rot/min] | 4,000 |

| Spindle Output [kW] | 30/22 |

| Spindle Torque [Nm] | 724/410 |

| Travel (X,Y,Z) [mm] | 695/1,585/300/235/1,540/1,540 |

| Rapid Travel (X,Y,Z) [m/min] | 48/48/36/24/36/30 |

| Slide Type | LM |

| No. of Tools | Mill head : 40T / Turret : 12T |

| Tool Size (turning/milling) [mm] | Mill head : D Ø130/ L450 / Turret : 25/Ø40 |

| Milling Tool Speed [rot/min] | Mill head : 12,000 / Turret : 5,000 |