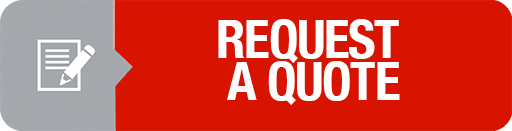

KF7300/5A

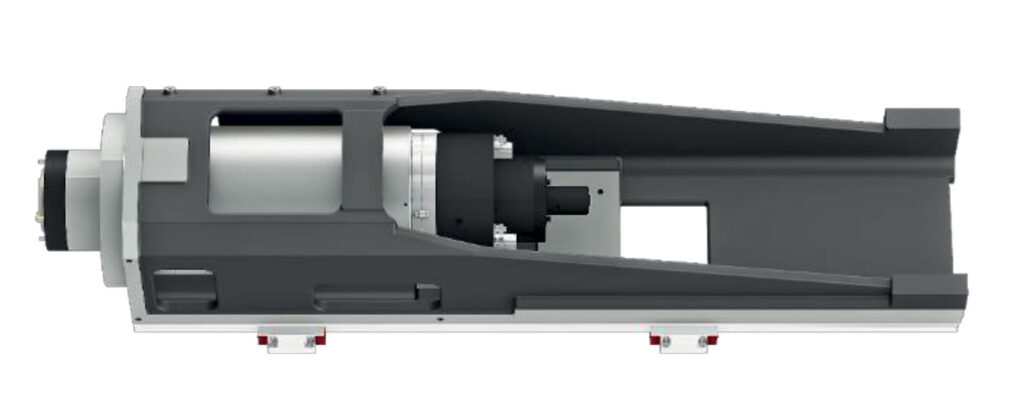

The Vertical Machining Center KF-5A Series designed by Hyundai WIA with years of expertise and the latest technology, ensures performance requirements of the mold industry. In addition, KF-5A Series can process products of various shapes with 5-axis table design.

- 5-axis table to satisfy various processing needs

- KF3500/5A : C Type, KF7300/5A : Wall type structure for stable machining ● HIgh speed built-in main spindle for the utmost quality of molds

- High-speed roller type LM guide in all axes

- Hyundai WIA mold package for optimal processing of mold parts

- Improved user convenience by applying the latest controller of FANUC

Wall Type Structure

The strucutre of KF7300/5A is a wall type for high-precision machining.

In particular, the feed is separated from the table to maintain high-precision machining even in heavy work.

Optimization of Installation Area

Installation is convenient even in small spaces with compact size of 10.1m2 and it improves space efficiency for the factory of customers.

Work table

5-axis Tilting Rotary Table Standard Application

The rotary table allows users to produce a wide range of complicated work pieces. It is possible to clamp each axis for extra rigidity and accuracy when machining.

Spindle

Direct Driven Spindle

The directly coupled spindle at a maximum revolution of 12,000 rpm [Opt.20,000 rpm], allows high-speed processing. Additionally, the large diameter and the thickness of the spindle add to the stability of the machine.

Built-in Spindle

The built-in spindle minimizes spindle vibration, enabling outstanding performance in a high-precision cutting environment such as complex shaped work-piece.

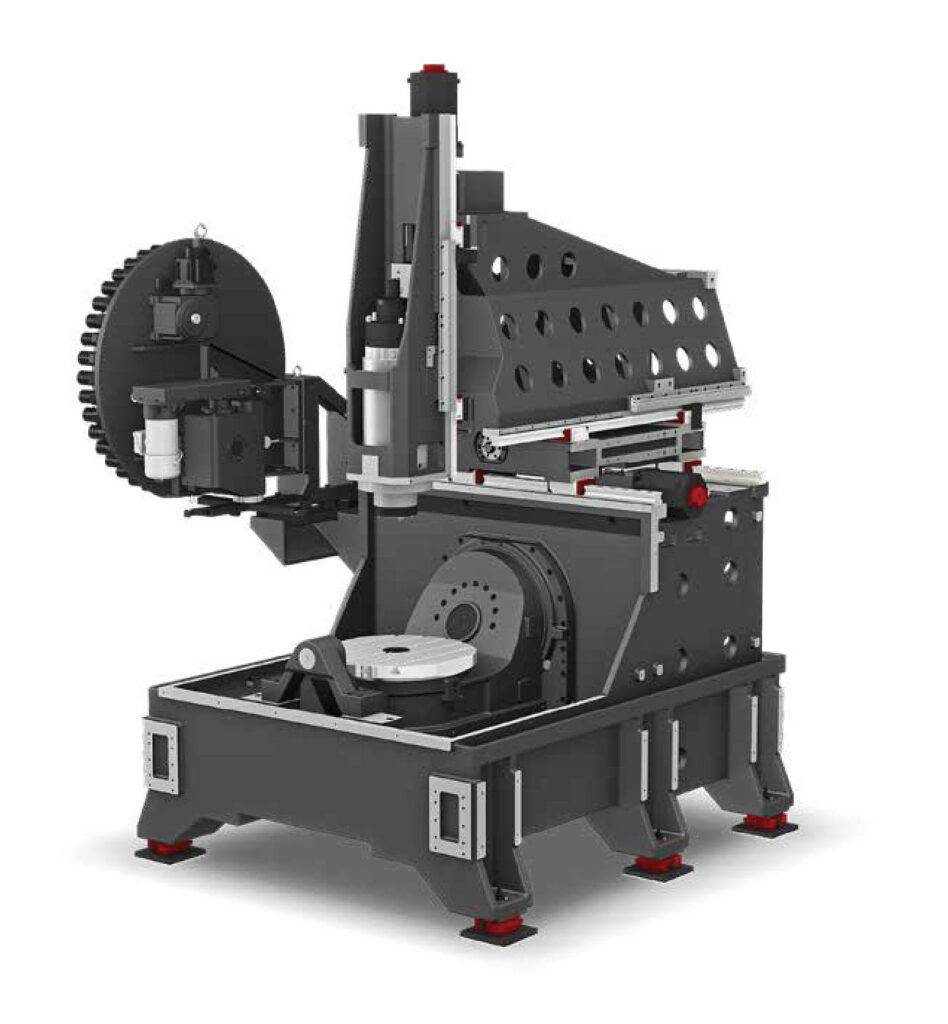

Ram Type Spindle

The main shaft of KF7300/5A is a ram-type application, which minimizes the weight of the transported body and greatly improves the dynamic performance.

Through Spindle Coolant [Option]

Through Spindle Coolant is exceedingly useful when drilling deep holes. It helps increase the lifetime of the tool, while decreasing cycle time.

High-Speed Roller LM Guideway

For processing the highest quality mold products, the KF7300/5A is designed with roller LM guideways for high rigidity and enhanced acc/ deceleration.

Grease Lubrication Method

Significant cost savings is achieved by incorporating the grease lubrication system versus the oil lubrication method.

ATC & Magazine

High Speed ATC

Position control through twin arm ATC on servo motors has been improved drastically. In addition, tool exchanging has become easier, reducing specific cutting time tremendously. Position control on the Twin Arm ATC has improved drastically. The twin arm ATC enables faster tool change and increased productivity.

Magazine

The tool magazine holds 30 tools as standard and 60 tools as an option. Due to the wider selection of tools and the random tool selection method, tool change time has improved.

(KF4600 II : Opt. 40 tools)

Direct Chip Discharge Structure

The structure was designed for the chip to fall directly to the lower part of the bed to improve chip discharge capability, and the high-temperature chips and coolant are discharged immediately without accumulating on the bed, minimizing thermal deformation of the structure.

Technical Specifications KF7300/5A

| Table Size [mm] | Ø630 mm [Ø730 mm] |

| Max. Load Capacity [kg] | 500 |

| Spindle Driving Method | Built-in |

| Spindle Taper | BBT40 [HSK-A63] |

| Spindle RPM [r/min] | 12,000 [20,000] |

| Spindle Power [kW] | 22/18.5 |

| Spindle Torque [Nm] | 204/119 N.m |

| Travel(X/Y/Z) mm | 765/650/520 |

| Rapid Feed Rate(X/Y/Z) [m/min] | 40/40/40 |

| Slide Type | LM |

| No. of Tools | 40 [60] |

| Tool Change Time (Chip To Chip) [sec] | 3.4 |