SE2200Y | SE2200LY | SE2200LSY

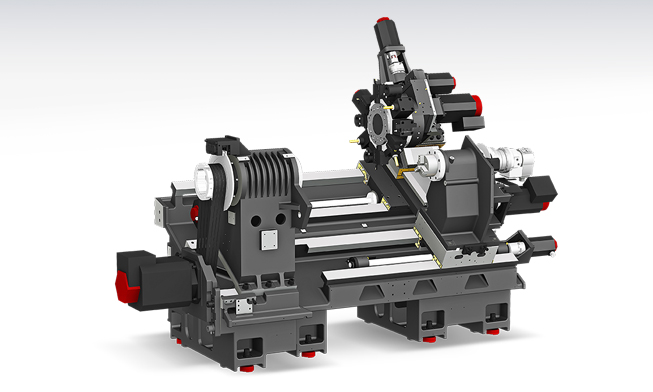

The CNC Turning Center SE-Y Series, designed with HYUNDAI WIA’s engineering expertise to by enhancing rigidity and accuracy of machining.

- 30° slanted one-piece bed structure with high rigidity

- Stabilized unit structure to minimize thermal displacement

- Integrated processing through synchronized control of Main/Sub spindle

- Multi-tasking operation with wedge type Y-axis BMT45P turret

- Ergonomic design for convenient access to chuck and tool

- Latest FANUC 0i PLUS Controller (15” touch screen)

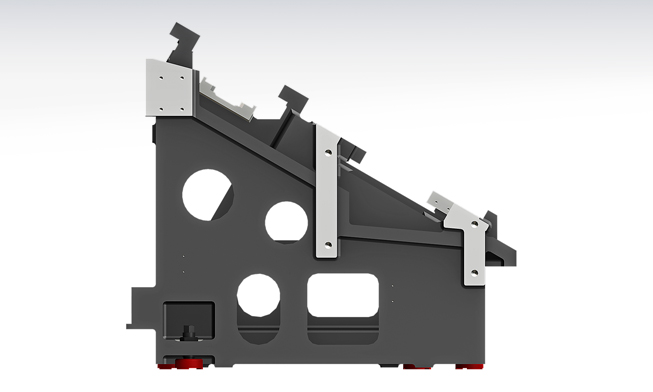

Optimal Bed Structural Analysis

Structural analysis was applied to the design of the machine to increase the tool post body and reduce the machine’s height so as to maintain the bed’s dynamic rigidity even during high-speed machining.

In addition, the SE-Y Series bed slope is pitched at 30 degrees to ensure more stable machining.

Guideway

High-Speed Roller LM Guideway

Linear roller guideways are applied to reduce non-cutting time and bring high rigidity.

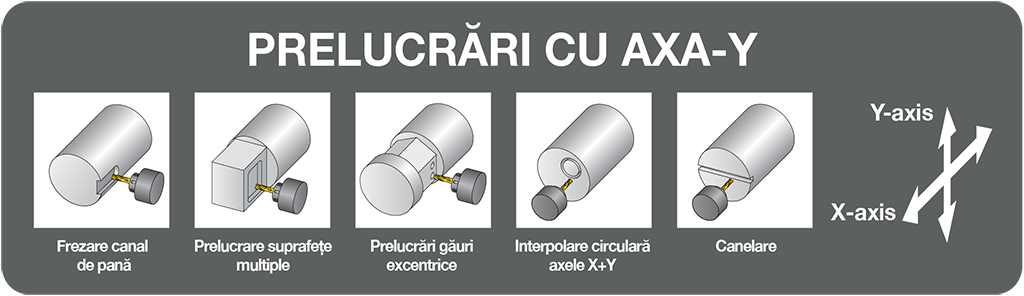

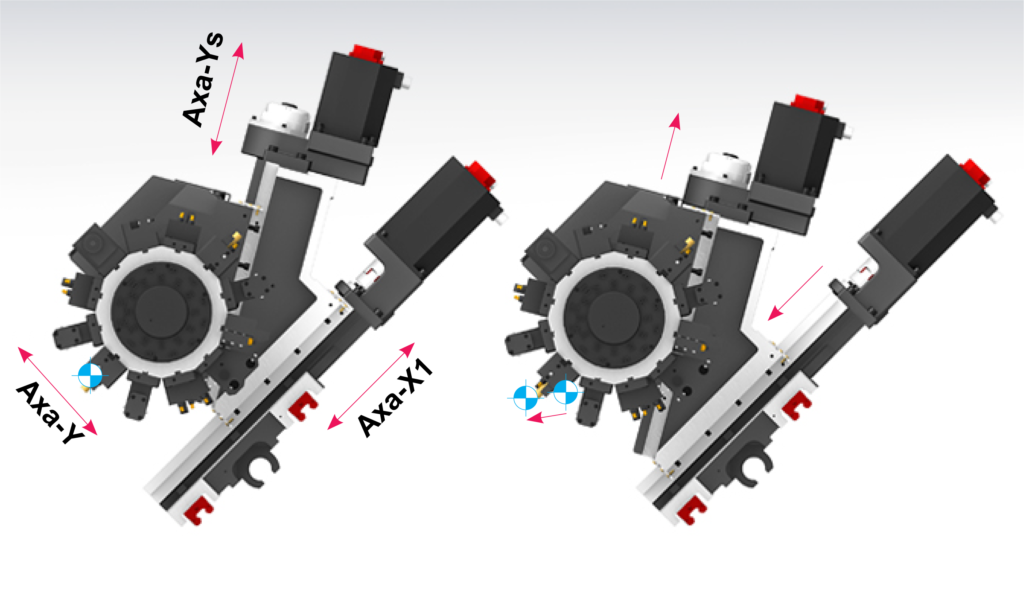

Y-axis Functions

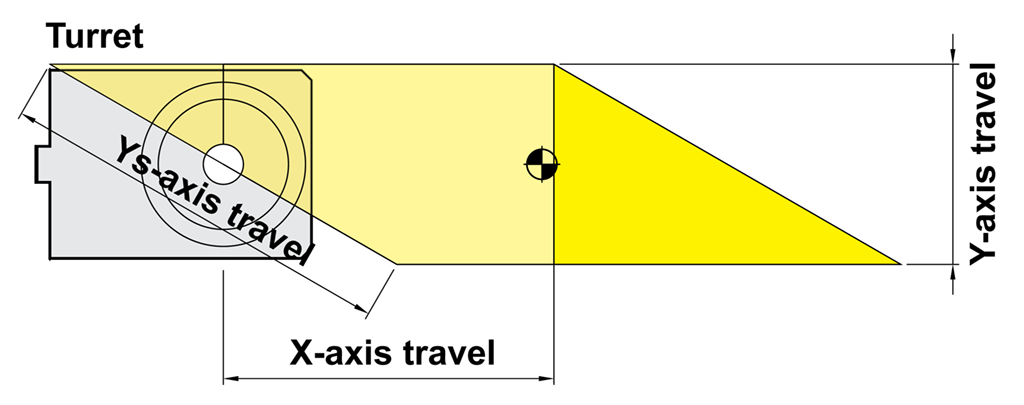

Wedge Type Y-Axis Structure

The SE-Y Series is designed with a wedge type Y-axis that is

transferred by the simultaneous operation of the Ys-axis and the X-axis.

In addtion, excellent rigidity makes it possible to perform superb quality when machining a high-accuracy machining.

Spindle for Heavy Cutting

The main spindle is designed with the same structure often found in larger sized machines. The combination of double cylindrical roller bearings and angular contact ball bearings leads to excellent heavy duty cutting performance.

Also, machining performance is enhanced by applying ribstar belt to minimize noise and belt slipping problems. The spindle is designed with a labyrinth structure to minimize possible bearing damage from coolant and to improve machining stability.

C-Axis Control

C-axis of SE-Y Series can be controlled to 0.001° which makes it possible to process various shapes..

SUB SPINDLE (‘SY’ Type)

The Belt-type sub spindle is designed to minimize thermal displacement during the continuous machining, offering from the heavy-duty cutting to the high-speed machining. When the main spindle cutting is completed, the sub spindle rotation is synchronized with the main spindle allowing the workpiece to be transferred to the sub spindle, and machining can begin on the back side of the workpiece.

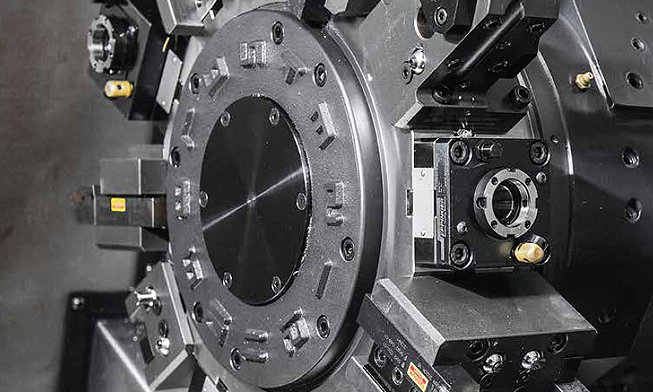

Turret

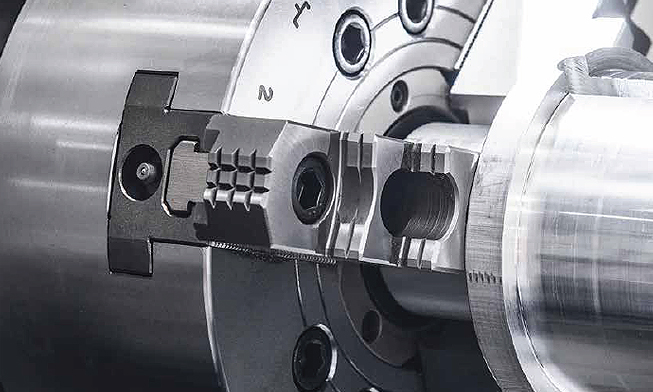

Mill Turret (BMT45)

The BMT turret secures the tool with four bolts and key on the tool mounting surface of the turret, making it possible to powerfully fix the tool, ensuring high reliability in rigidity and precision.

Mill Tool Holder

Machining capability has increased with the addition of straight milling head tool holder.

Special Tool

With the Y-axis, the SE-Y Series can process high value-added products using a variety of rotating tools. In particular, there is a multi-holder for attaching a variety of tools to one holder, and an eccentric rotary tool for handling eccentric parts without additional axis travel, which can realize integration of process with one machine.

Hydraulic NC Tailstock with Position Control (‘L’ Type Standard)

The hydraulic NC tailstock applied to the SE series enables independent transfer through a program independently of the turret movement and it simultaneously achieved “Improvement of user convenience” and “Reduction of cycle time”.

Numerical control FANUC 0i Plus

The FANUC 0i-F Plus numerical control offers a simple, cost-optimized solution for most general processing applications. Ready to use, it boasts state-of-the-art hardware and a complete standard software package for most turning and milling processes.

Customization features are already included and provide an easy way to create application-tailored HMI screens. The 0i-F Plus series is also fully compatible with older FANuC 0 and 0i CNCs and has the same programming as more advanced FANuC controls. The advantage is that existing programs can be used immediately and that new programs can be developed. Offering the high performance offered by FANUC servo technology, this CN offers the same easy-to-use comfort across the range.

SE-Y turning centers with high precision in machining

Automatic Q-Setter

Cutting tools are calibrated quickly and accurately with the addition of a q-setter. Each tool tip is touched off manually using a sensor that inputs the position automatically.

Linear Scale

Linear scales increase positioning accuracy and reduce distortion caused by thermal growth, thus ensuring a more accurate finished part.

Work Probe

Workpiece coordinate values can be set automatically using the optional spindle probe.

Technical SpecificationsSE2200Y

| Max Turning Dia [mm] | 300 |

| Max Turning Length [mm] | 288 |

| Driving Method | Belt |

| Chuck Size [inch/mm] | 8″/203,2 |

| Spindle RPM [rot/min] | 4,500 |

| Spindle Output [kW] | 15/11 |

| Spindle Torque [Nm] | 167/92 |

| Travel (X/Y/Z/ZB) [mm] | 210/110/340/- |

| Rapid Travel (X/Y/Z/ZB) [m/min] | 30/10/36/- |

| Slide Type | LM |

| No. of Tools | 12 |

| Tool Size (turning/milling) [mm] | 20/32 |

| Milling Tool Speed [rot/min] | 6,000 |

Technical SpecificationsSE2200LY

| Max Turning Dia [mm] | 300 |

| Max Turning Length [mm] | 508 |

| Driving Method | Belt |

| Chuck Size [inch/mm] | 8″/203,2 |

| Spindle RPM [rot/min] | 4,500 |

| Spindle Output [kW] | 15/11 |

| Spindle Torque [Nm] | 167/92 |

| Travel (X/Y/Z/ZB) [mm] | 210/110/560/- |

| Rapid Travel (X/Y/Z/ZB) [m/min] | 30/10/36/- |

| Slide Type | LM |

| No. of Tools | 12 |

| Tool Size (turning/milling) [mm] | 20/32 |

| Milling Tool Speed [rot/min] | 6,000 |

Technical SpecificationsSE2200LSY

| Max Turning Dia [mm] | 300 |

| Max Turning Length [mm] | 508 |

| Driving Method | Belt |

| Chuck Size [inch/mm] | 8″/203,2 5″/127 |

| Spindle RPM [rot/min] | 4,500 |

| Spindle Output [kW] | 15/11 |

| Spindle Torque [Nm] | 167/92 |

| Travel (X/Y/Z/ZB) [mm] | 210/110/560/560 |

| Rapid Travel (X/Y/Z/ZB) [m/min] | 30/10/36/15 |

| Slide Type | LM |

| No. of Tools | 12 |

| Tool Size (turning/milling) [mm] | 20/32 |

| Milling Tool Speed [rot/min] | 6,000 |