KBN135 / KBN135C Horizontal Boring Centers

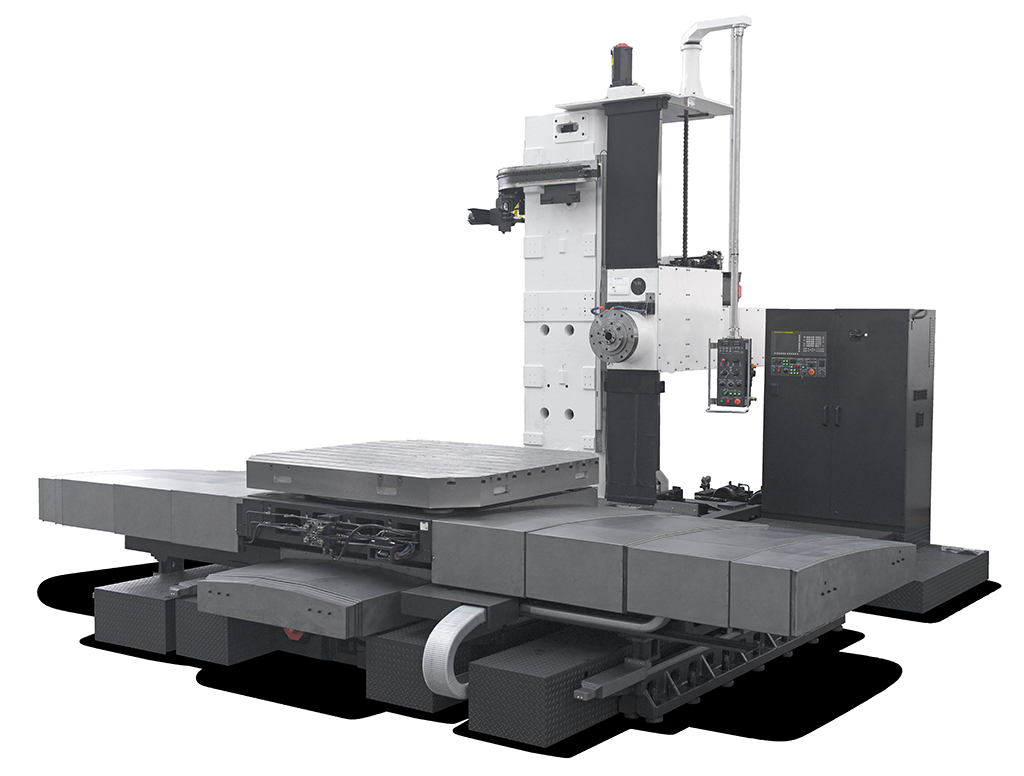

- Single unit bed for X and Z axis for ultra-precision (KB135)

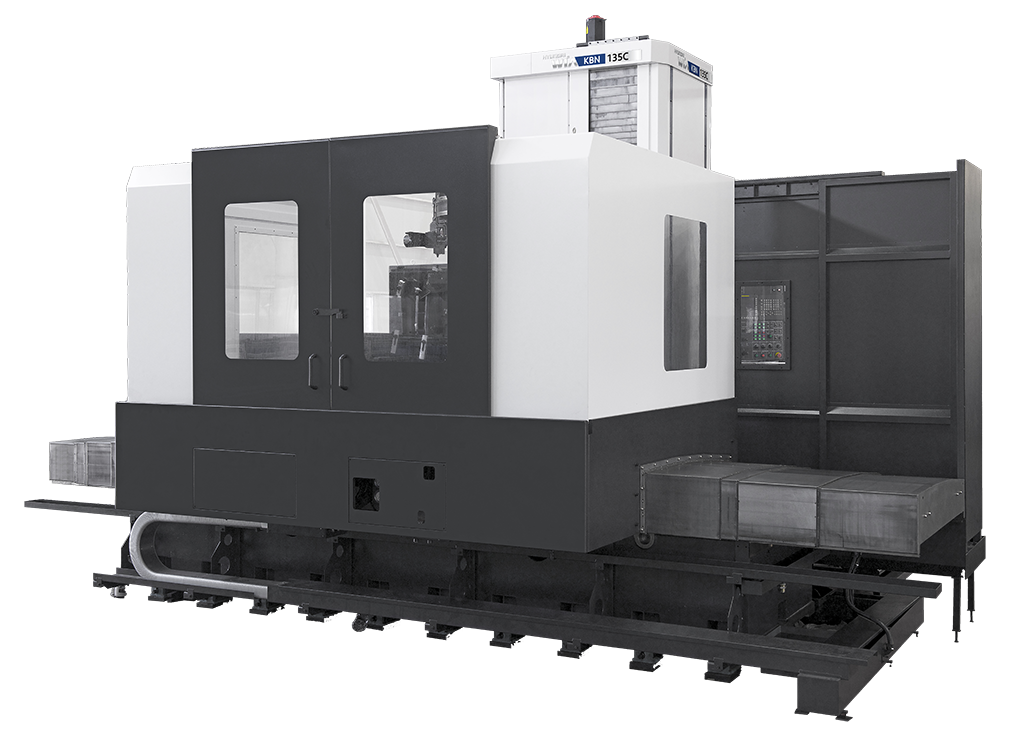

- Movable column structure for high-load, heavy duty cutting needs (KB135C)

- Selectable X and Y axis of up to 1,000mm (39.3″) and 500mm (19.6″) respectively

- 3-step gear drive main spindle for heavy duty cutting

- Optimal boring capability with W-axis maximum travel of 700mm(27.5″)

- Equipped with standard linear and rotary scales for ultra-precision

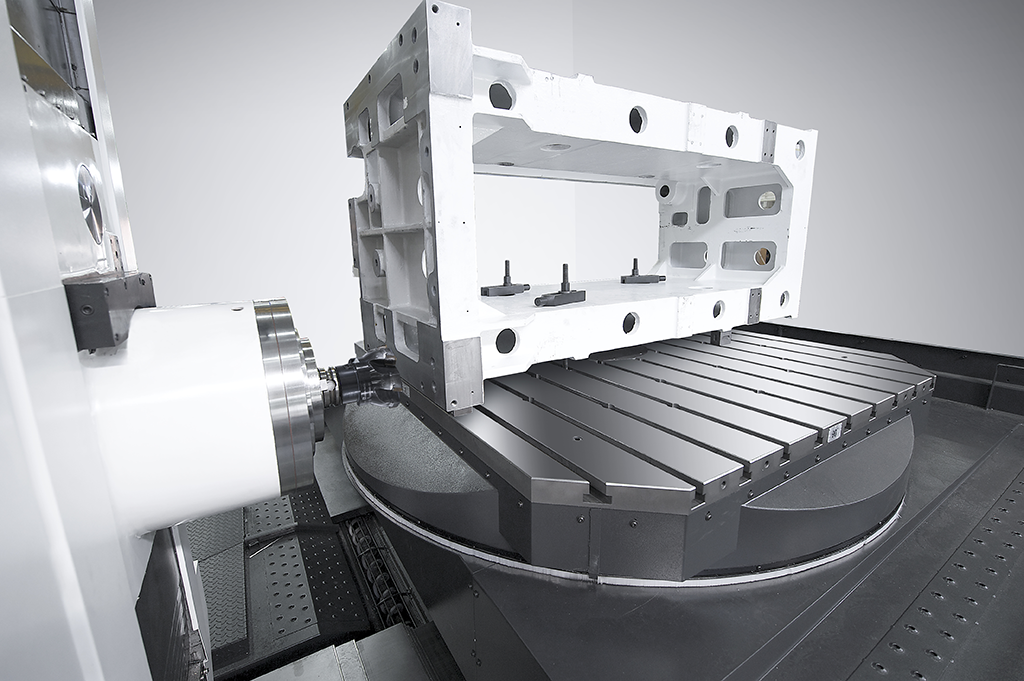

KBN Horizontal Boring Centers have high rigidity, high precision and high torque are key elements for the successful manufacture of components for the energy industry. The Kund 135 and KBN 135C from Hyundai WIA are designed to handle the production of large and heavy parts.

KBN series machines are standard with a torque of 2295 ft-lbs (optional 2,712 ft-lbs.), Ideal for machining large parts with ease and precision.

For heavy-duty cutting applications, the KBN series is available with a 3-speed main shaft transmission running at 2,500 RPM.

To cover a wide variety of applications, the Hyundai WIA has the standard KBN 135 with a movable table and KBN 135C which is equipped with a movable column on the Z axis. The advantages of the horizontal movable column include increased rigidity and reduced heat generation.

With a quick tool change time on the KBN 135C of 33.2 seconds chip-to-chip (70 sec. On the KBN 135), the KBN series reduces idling time and improves productivity, making it an option for large machining applications high precision.

A high level of production flexibility is achieved with the KBN series by offering a standard 60-tool shop (120 tools optional). The maximum tool length on KBN 135 and 135C is 23.6 “.