LV800RM | LV800LM

The Hyundai-WIA LV800 vertical CNC lathe has a rigid and stable heavy-duty cutting platform with a one-piece, square-type column that provides maximum stability.

- Stable shaft structure with excellent cutting capacity for heavy loads

- 2-step chuck pressure mechanism adopted to minimize deformation of the workpiece

- Various peripherals can be used for optimized processing

- Designed for optimal chip evacuation

- Mirror construction for practical automation solutions

Structural design

Right and Left Machine Structure

The LV800 vertical cnc lathe consists of the machine configuration in the mirror (left and right) allowing more efficient automation options (except LV1100).

Frontal operation

The power supply, hydraulic device and lubrication device are all designed to be accessed from the front, which leads to user comfort.

Fixed or movable column

Fixed column

The LV800 vertical CNC lathe is designed with a fixed column to reduce vibration during axial movements.

Moving Colum

The LV800 Series Features a traveling column to maintain superior accuracy when turning larger work pieces.

Frame

Step frame structure

For the LV800 series, the main movement of the column is adjusted in steps so that the load generated in front during the processing operations is reduced to a minimum. Also, by optimizing the weight of the column, the stability of the feed is improved.

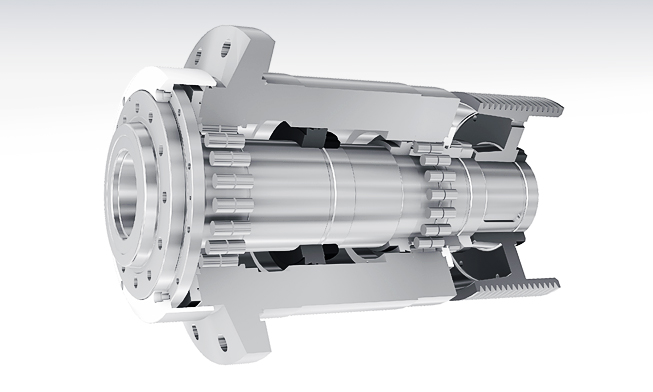

Spindle

Spindle for Heavy Cutting

The use of both cylindrical roller bearings and angular contact bearings provide high speed and rigidity. This enables machining of heavy workpieces.

Also, LV800 Series is with a gear box spindle, which provides high torque at low rpm and stability at high rpm.

C-Axis Control (‘M’ Type)

The C-axis is capable of 0.001° control when milling turret is applied. Machining capability is strengthened with turning and milling operations.

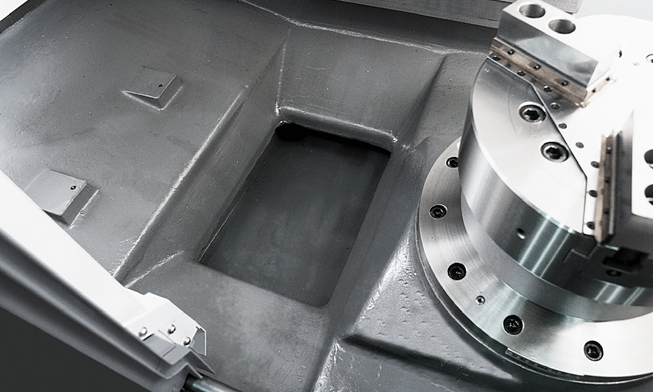

Chip Influx Protection

Chute Structure

The LV Series is incorporated with a protection device to keep chips and other foreign materials from entering the main spindle, ensuring long term high precision performance.

The sloped bed design improves chip flow and disposal of cutting fluids minimizing thermal displacement.

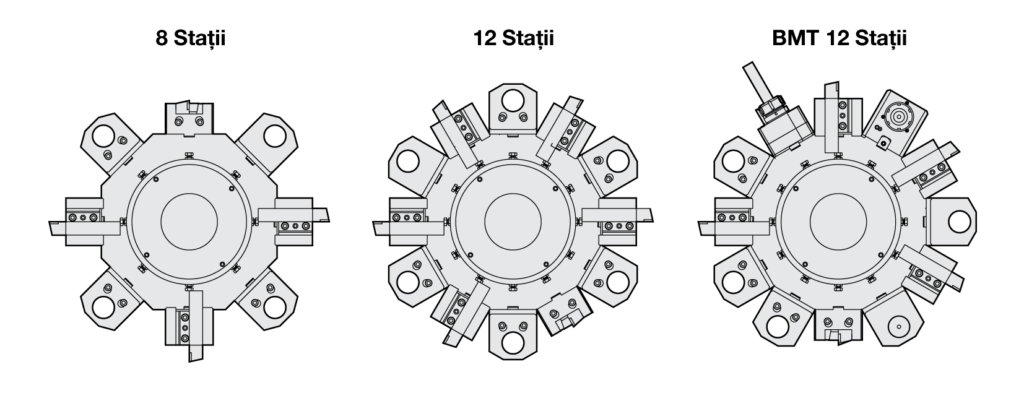

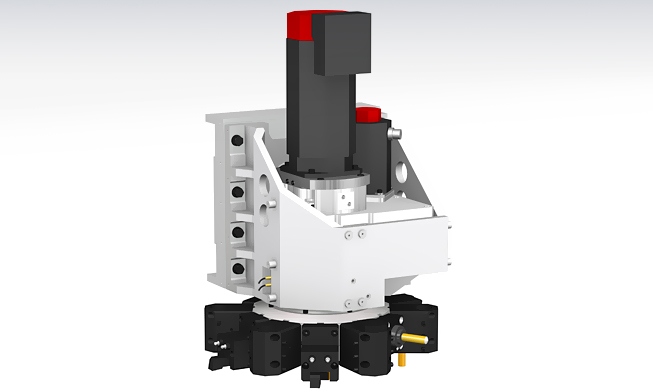

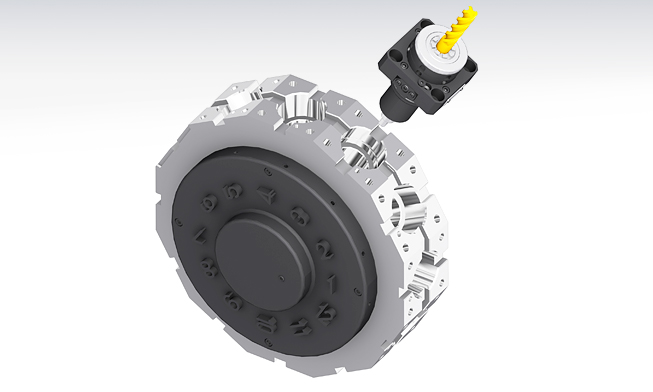

Servo Turret

The LV Series’ machining reliability is enhanced by incorporating a

high performance AC servo motor to the turret drive mechanism.

Also, the turrets are installed with 3 piece couplings to improve

indexing accuracy. Powerful hydraulic tool clamping exhibits great

heavy duty machining performance by minimizing tool tip deviation

due to work load

Mill Turret

BMT Turret (‘M’ Type)

Machining capability has increased with the addition of straight milling head tool holder, which can machine workpieces from the side, and angular milling head tool holder, which can perform I.D. operations.

Milling tool holder

The machining capacity has increased with the addition of the straight milling head tool holder, which can process parts sideways, and the angular milling tool holder holder, which can perform various machining functions.

Technical Specification LV800RM

| Max Turning Dia [mm] | 800 |

| Max Turning Length [mm] | 800 |

| Driving Method [tip antrenare] | Curea |

| Chuck Size [inch/mm] | 18″/457,2 |

| Spindle RPM [rot/min] | 2,000 |

| Spindle Output [kW] | 30/22 |

| Spindle Torque [Nm] | 1,619/1,188 |

| Travel (X,Y) [mm] | 400/800 |

| Rapid Travel [m/min] | 20/20 |

| Slide Type [tip] | Liniare |

| No. of Tools | 12 |

| Tool Size [mm] | 32/50 |

| Milling Tool Speed [rot/min] | – |

Technical Specification LV800LM

| Max Turning Dia [mm] | 800 |

| Max Turning Length [mm] | 800 |

| Driving Method [tip antrenare] | Curea |

| Chuck Size [inch/mm] | 18″/457,2 |

| Spindle RPM [rot/min] | 2,000 |

| Spindle Output [kW] | 30/22 |

| Spindle Torque [Nm] | 1,619/1,188 |

| Travel (X,Y) [mm] | 400/800 |

| Rapid Travel [m/min] | 20/20 |

| Slide Type [tip] | Liniare |

| No. of Tools | 12 |

| Tool Size [mm] | 32/50 |

| Milling Tool Speed [rot/min] | 3,000 |