E160A | E160C

The Series E160 CNC lathe, designed by Hyundai WIA with years of experience and state-of-the-art technology, maximizes productivity, increasing both technical performance and economic efficiency.

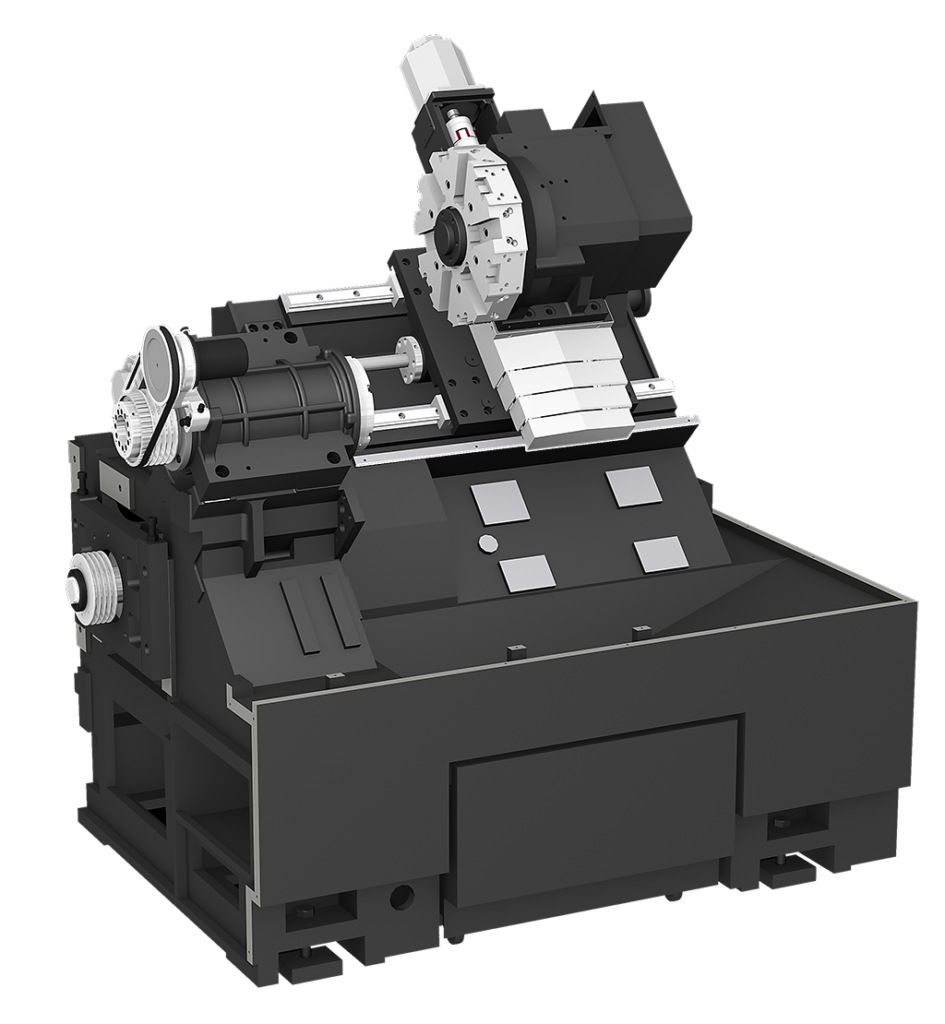

- 45° slanted one-piece rigid bed structure

- Minimal thermal distortion

- Machine structure designed to maximize productivity

- Best in class rapid traverse rate : 30m/min

- The most reliable high speed servo turret : 0.1sec/step

- Environmental friendly, separate coolant and lubrication design

- Compact design, able to install within a limited space.

- Ergonomic design allows convenient access to chuck and tools

High Precision & Rigidity One-piece Structure

The E160 Series CNC lathe is designed with a 45 degree slanted bed combined with square type and tube type rib structure. This special design enhances rigidity and vibration absorbing capability, allowing powerful cutting with high precision.

Guideway

LM Guideway

LM guideway with the rapid traverse rate of 30 m/min (1,181ipm) is

installed on E160 Series.

LM guideway maintains high precision even after a long periods of

operation. LM guideway`s wide surface minimizes attrition and slipping

which can occur often during machining.

Ball Screw

In order to eliminate thermal growth and increase accuracy, all axis are

driven by high precision double anchored ballscrews

Spindle

Strung-urile CNC Seria E160 a fost proiectat cu o structură de fus precisă The E160 Series spindle was designed with a precise and highly rigid spindle structure by adopting a high speed angular ball bearing in the DB array. To ensure good safety in the powerful and heavy cutting, the spindle is designed with an angular bearing structure with P4 class.

Turret

Continued accuracy of the turret indexing position is maintained by a

powerful, high speed servo motor. The 3 piece coupling and non-lift method applied design prevents foreign material from getting into the turret.

Numerical control FANUC 0i Plus

FANUC 0i Plus Numerical ControlFANUC 0i-F Plus Numerical Control offers a simple, cost-optimized solution for most general processing applications. Ready to use, it boasts state-of-the-art hardware and a complete standard software package for most turning and milling processes

Customization features are already included and provide an easy way to create application-tailored HMI screens. The 0i-F Plus series is also fully compatible with older FANuC 0 and 0i CNCs and has the same programming as more advanced FANuC controls. The advantage is that existing programs can be used immediately and that new programs can be developed. Offering the high performance offered by FANUC servo technology, this CN offers the same easy-to-use comfort across the range.

Technical specifications E160A

| Max Turning Dia [mm] | 280 |

| Max Turning Length [mm] | 300 |

| Driving Method[tip antrenare] | Curea |

| Chuck Size [inch/mm] | 6″/152.4 |

| Spindle RPM [rot/min] | 6,000 |

| Spindle Output [kW] | 11/7.5 |

| Spindle Torque [Nm] | 35.8/70 |

| Travel (X,Y) [mm] | 165/330 |

| Rapid Travel [m/min] | 30/30 |

| Slide Type [tip] | Liniare |

| No. of Tools | 12 |

| Tool Size [mm] | 20/32 |

Specificații Tehnice E160C

| Diametru Max. [mm] | 280 |

| Lungimea Max. [mm] | 280 |

| Arbore principal [tip antrenare] | Curea |

| Diametru universal [inch/mm] | 8″/203.2 |

| Viteza arbore principal [rot/min] | 4,000 |

| Putere Motor [kW] | 11/7.5 |

| Cuplu Arbore [Nm] | 64.4/126 |

| Curse (X,Y) [mm] | 165/330 |

| Curse rapide [m/min] | 30/30 |

| Ghidaje [tip] | Liniare |

| Numar de scule | 10 |

| Dim.scule (strunjire/frezare) [mm] | 25/32 |