SE2600 | SE2600M

The SE2600 CNC lathes series from Hyundai-WIA offers a range of machining up to Ø10″ quality and rigid throughout the manufacturing life.

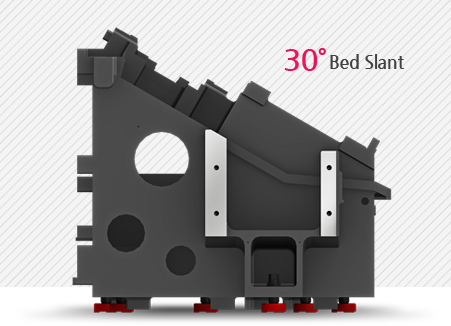

- 30° slanted one-piece bed structure with high rigidity

- Ensured high-rigidity applying Roller guideway on all axes (X/Z-axis: 30/30 m/min)

- High-rigidity and high-speed servo turret (Expanded disk width)

- Improved user convenience by applying the latest controller of FANUC

- Ergonomic design for convenient access to chuck and tool

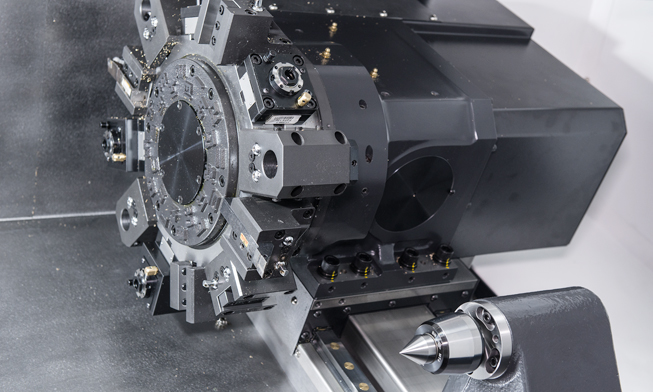

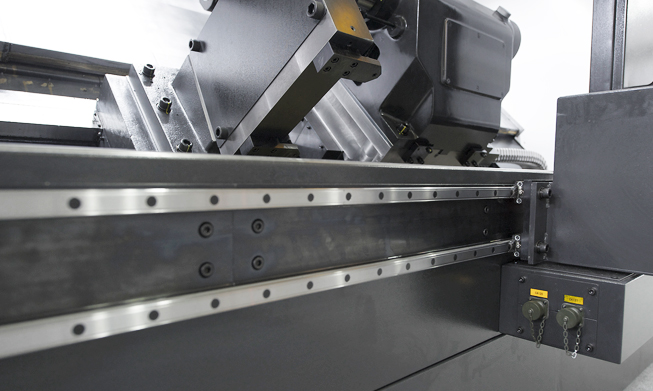

Monobloc rigid bed

Structural analysis was applied to design the SE2600 CNC lathes to increase the tool post body and reduce the machine’s height so as to maintain the bed’s dynamic rigidity even during high-speed machining. In addition, the SE Series bed slope is pitched at 30 degrees to ensure more stable machining.

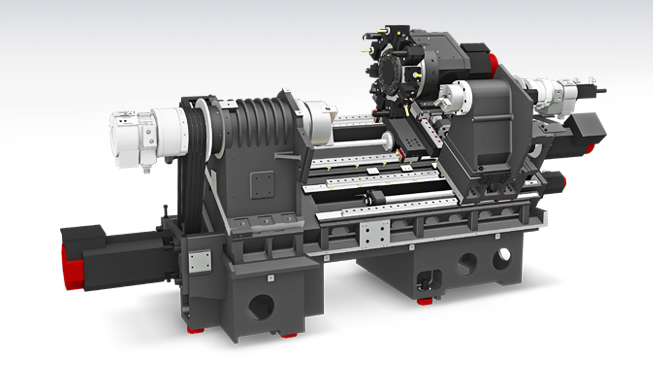

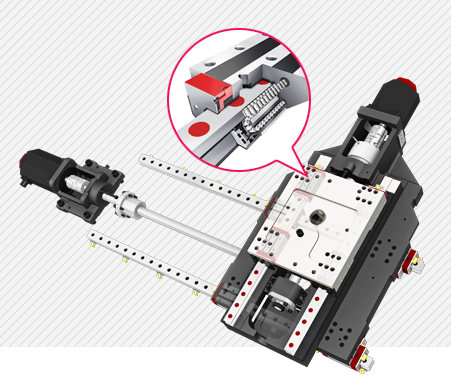

Guideway

High-Speed Roller LM Guideway

Linear roller guideways are applied on SE2600 CNC lathes to reduce non-cutting time and bring high rigidity.

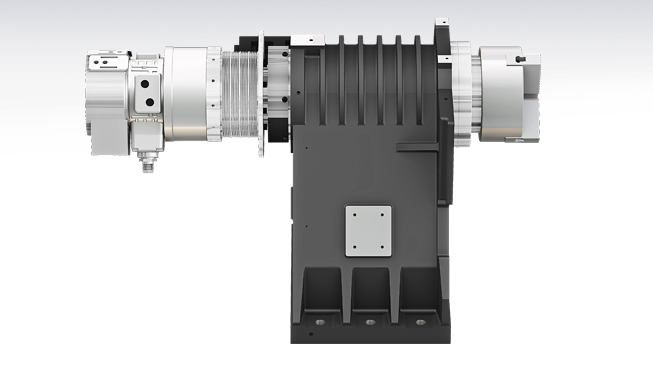

MAIN SPINDLE

Specialized in High-speed and Rough Cutting

The 10” main spindle is designed for high-speed machining by applying two and three-row ball bearings to the front and rear, respectively. In addition, the main spindles are designed to match the rigid spindle structure by combining the double-row roller bearing and the angular contact bearing, which provides excellent performance for heavy-duty cutting.

Moreover, we applied the ribstar belt to minimize the slip and noise of the belt during processing, and this improvement enhanced performance of the work and increased processing stability by minimizing bearing damage caused by inflow of the oil.re specialized in fast and hard cutting and milling operations

Re-specialized in fast and hard cutting and milling operations

The processing performance is improved by applying the Ribstar belt to minimize noise and belt slip problems. The shaft is designed as a maze structure to reduce possible bearing damage caused by the coolant and to improve machining stability.

C-Axis Control

C-axis of SE Series can be controlled to 0.001° which makes it possible to process various shapes.

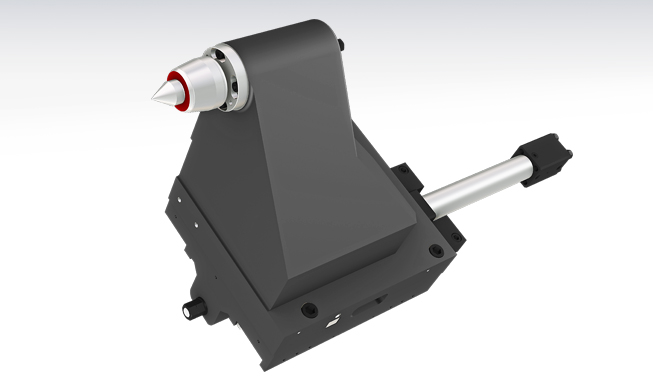

NC Tailstock

Tailstock (hydraulically operated) with numerical position control (for standard “L” type lathes).

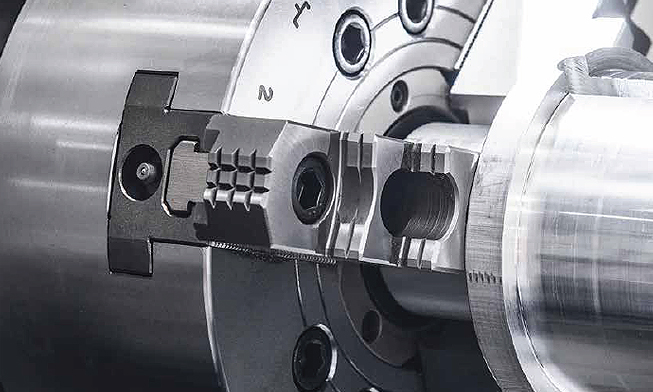

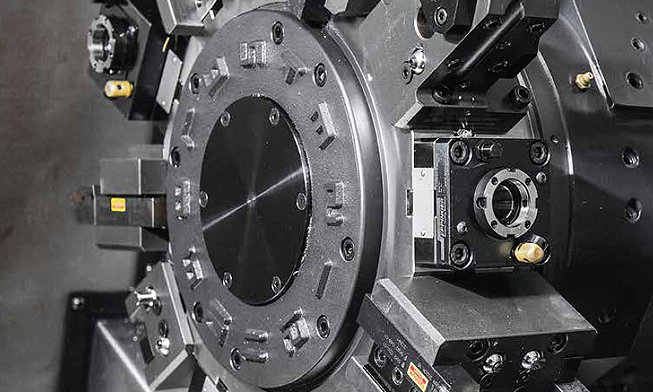

SERVO TURRET

The turret of SE series is applied with high performance AC servo motor, improving machining reliability. 3-piece coupling shows excellent performance in indexing. Powerful hydraulic tool clamping minimizes tool tip deviation caused by load.

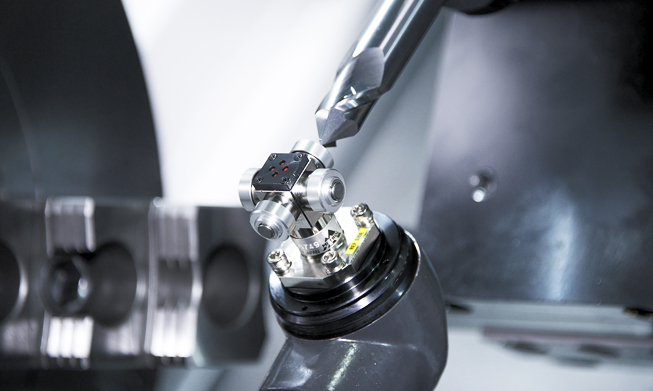

Mill Tool Holder

Machining capability has increased with the addition of straight milling head tool holder.

70Bar High Pressure Coolant

Turret is designed to utilize 70bar high pressure coolant and it shows optimum performance in machining difficult-to-cut material.

BMT45 Turret (Mill Turret)

The BMT turret secures the tool with four bolts and key on the tool mounting surface of the turret, making it possible to powerfully fix the tool, ensuring high reliability in rigidity and precision.

Numerical control FANUC 0i Plus

The FANUC 0i-F Plus numerical control offers a simple, cost-optimized solution for most general processing applications. Ready to use, it boasts state-of-the-art hardware and a complete standard software package for most turning and milling processes.

Customization features are already included and provide an easy way to create application-tailored HMI screens. The 0i-F Plus series is also fully compatible with older FANuC 0 and 0i CNCs and has the same programming as more advanced FANuC controls. The advantage is that existing programs can be used immediately and that new programs can be developed. Offering the high performance offered by FANUC servo technology, this CN offers the same easy-to-use comfort across the range.

Additional functions

Q-Setter automat

The cutting tools are calibrated quickly and accurately, with the addition of a q setting (mini feeler sensor). Each tool tip is touched manually using a sensor that automatically enters the position.

Linear optical rulers

Linear optical rulers increase positioning accuracy and reduce distortion caused by thermal deformation, thus ensuring a more precise finished part.

Technical Specifications SE2600

| Max Turning Dia [mm] | 460 |

| Max Turning Length [mm] | 660 |

| Driving Method [tip antrenare] | Belt |

| Chuck Size [inch/mm] | 10″/254 |

| Spindle RPM [rot/min] | 3,500 |

| Spindle Output [kW] | 18.5/11 |

| Spindle Torque [Nm] | 470.9/286.4 |

| Travel (X,Y) [mm] | 265/680 |

| Rapid Travel [m/min] | 30/30 |

| Slide Type [tip] | LM |

| No. of Tools | 10 |

| Tool Size [mm] | 25/40 |

| Milling Tool Speed [rot/min] | – |

Technical Specifications SE2600M

| Max Turning Dia [mm] | 380 |

| Max Turning Length [mm] | 610 |

| Driving Method [tip antrenare] | Belt |

| Chuck Size [inch/mm] | 10″/254 |

| Spindle RPM [rot/min] | 3,500 |

| Spindle Output [kW] | 18.5/11 |

| Spindle Torque [Nm] | 470.9/286.4 |

| Travel (X,Y) [mm] | 265/680 |

| Rapid Travel [m/min] | 30/30 |

| Slide Type [tip] | LM |

| No. of Tools | 12 |

| Tool Size [mm] | 25/40 |

| Milling Tool Speed [rot/min] | 6,000 |