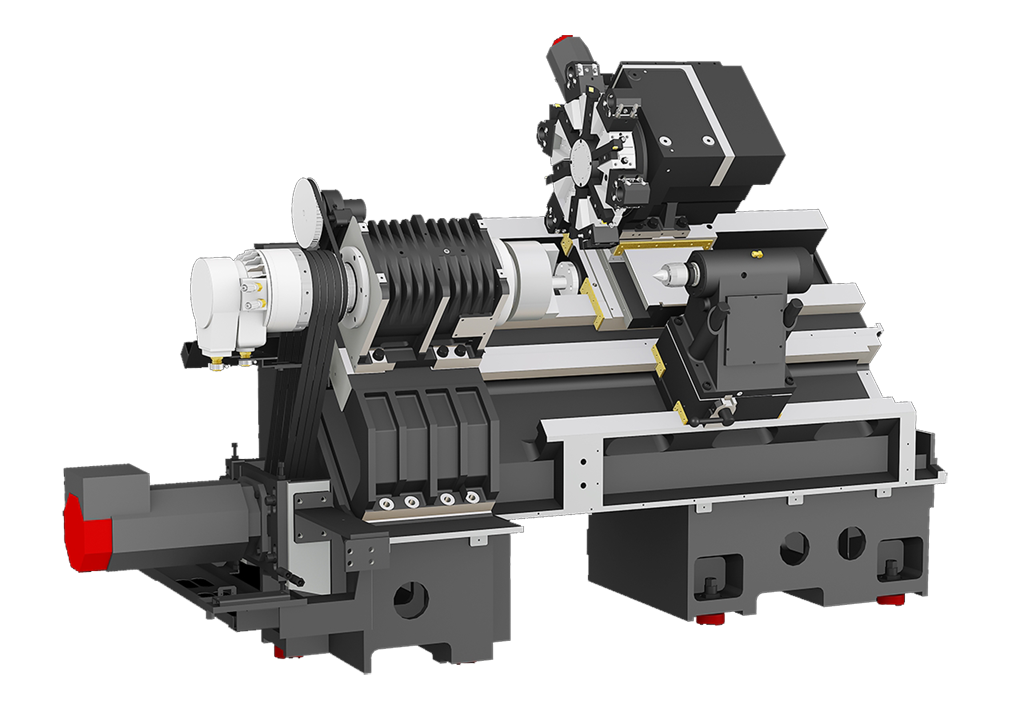

HD2200 | HD2200C | HD2200M | HD2200MC

The CNC Turning Center HD2200 Series, designed by Hyundai WIA with years of expertise and the latest technology, is a Turning Center that maximizes productivity and performance.

- 45° slanted one-piece rigid bed structure

- Minimal thermal distortion

- User-friendly structure for high productivity

- Best in class rapid traverse rate : 30m/min (Z-axis)

- Reliable, high speed servo turret: 0.12sec/step

- Box guide ways for heavy-duty cutting

- Compact design, able to install within a limited space.

- Ergonomic design for convenient access to chuck and tool

High Rigidity, One-Piece Bed Structure

The bed structure of the HD2200 is designed with combination of square type and tubular rib structure. It has a slope of 45 ° which helps maintain high rigidity. It shows great performance in heavy duty cutting, absorbing vibration and maintaining accuracy.

Integrated Coolant Tank

The coolant tank is changed from separate structure to one-piece structure to prevent overflow and clogging.

It is possible to remove chips from right side of the machine which enhances chip removal capability

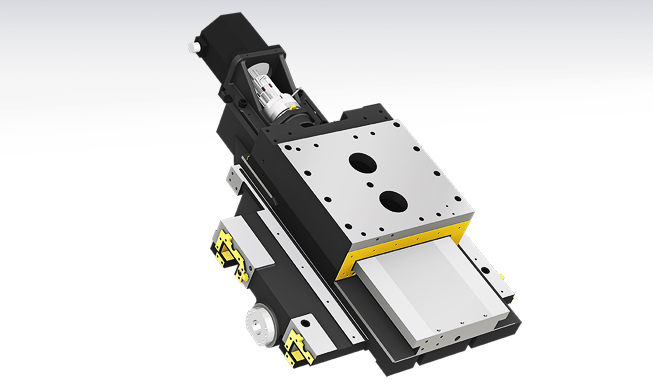

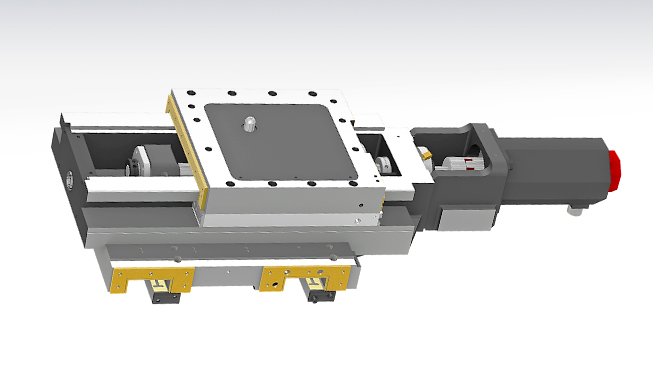

Guideway

Box Guideway

All axes of HD2200 are designed with Box Guideways for better travel

ability. Box Guideways show great performance in offsetting vibrations

caused by heavy duty cutting.

Sealed GIB Structure

X-axis of HD2200 is designed to minimize the damage of turcite from

chips by applying the sealed GIB structure.

Z-Axis High Performance Motor

Z-axis feed ability is improved by installing high performance servo motor.

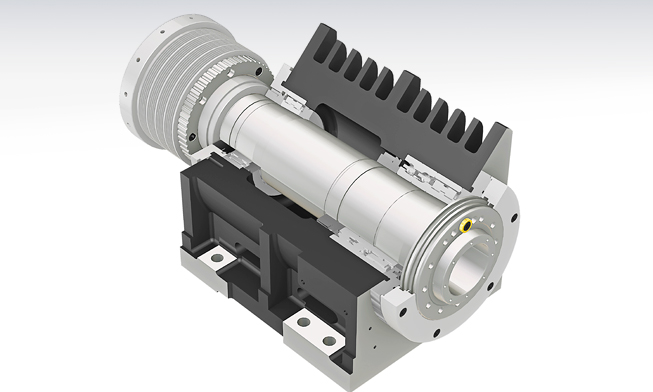

Main Spindle

Spindle for Heavy Cutting

The main spindle is designed with the same structure as that

often found in larger sized machines. The combination of double

cylindrical roller bearings and angular contact ball bearings leads to

excellent heavy duty cutting performance.

Ribstar Belt

Also, machining performance is enhanced by applying ribstar belt to

minimize noise and belt slipping problems. The spindle is designed with a labyrinth structure to minimize possible bearing damage from coolant and to improve machining stability.

C-Axis Control (‘M’ Type)

C-axis of HD2200 Series can be controlled to 0.001° which makes it possible to process various shapes.

Tail Stock

MT#4 Tail Stock. Tailstock enables stable machining of high quality products where quill travels up to 80mm (3″). (MT#5 Tail Stock : Option)

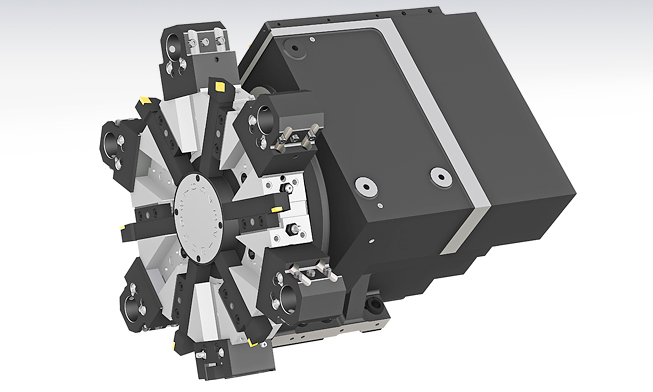

Turret

HD2200/C Servo Turret

The turret of HD2200 is applied with high performance AC servo motor, improving machining reliability. 3-piece coupling shows excellent performance in indexing. Powerful hydraulic tool clamping minimizes tool tip deviation caused by load.

To enhance rigidity, M10 bolts are used to fix holders and M12 bolts are used to fix boring bar holders.

HD2200M/MC BMT55P Turret (Mill Turret)

The BMT turret secures the tool with four bolts and key on the tool

mounting surface of the turret, making it possible to powerfully fix the

tool, ensuring high reliability in rigidity and precision.

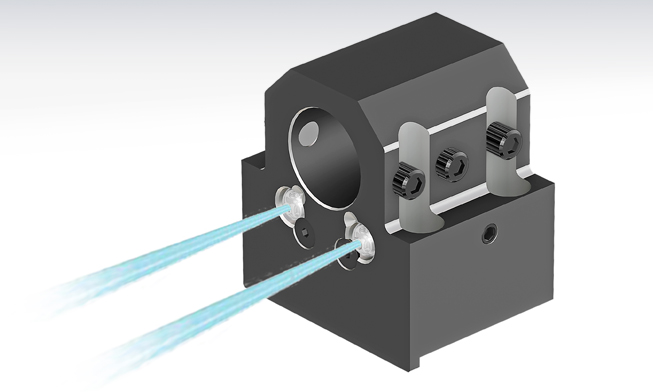

Mill Tool Holder

Machining capability has increased with the addition of

straight milling head tool holder, which can machine

workpieces from the side, and angular milling head tool

holder, which can perform I.D. operations.

Special Tool

The HD2200 series can process high value-added products using a variety of rotating tools. In particular, there is a multi-holder for attaching a variety of tools to one holder, and an eccentric rotary tool for handling eccentric parts without additional axis travel, which can realize integration of process with one machine.

HD2200 high precision CNC turning center

Automatic Q-Setter

Cutting tools are calibrated quickly and accurately with the addition of a q-setter. Each tool tip is touched off manually using a sensor that inputs the position automatically.

Linear Scale

Linear scales increase positioning accuracy and reduce distortion caused by thermal growth, thus ensuring a more accurate finished part.

Work Probe

Workpiece coordinate values can be set automatically using the optional spindle probe.

Technical Specifications HD2200

| Max Turning Dia [mm] | 380 |

| Max Turning Length [mm] | 565 |

| Driving Method | Belt |

| Chuck Size [inch/mm] | 8″/203,2 |

| Spindle RPM [rot/min] | 4,500 |

| Spindle Output [kW] | 18.5/15 |

| Spindle Torque [Nm] | 206/125.3 |

| Travel (X,Y) [mm] | 215/580 |

| Rapid Travel [m/min] | 24/30 |

| Slide Type | BOX |

| No. of Tools | 12 |

| Tool Size (turning/milling) [mm] | 25/40 |

Technical Specifications HD2200C

| Max Turning Dia [mm] | 380 |

| Max Turning Length [mm] | 550 |

| Driving Method | Belt |

| Chuck Size [inch/mm] | 10″/254 |

| Spindle RPM [rot/min] | 3,500 |

| Spindle Output [kW] | 18.5/15 |

| Spindle Torque [Nm] | 403.6/245.4 |

| Travel (X,Y) [mm] | 215/580 |

| Rapid Travel [m/min] | 24/30 |

| Slide Type | BOX |

| No. of Tools | 12 |

| Tool Size (turning/milling) [mm] | 25/40 |

Technical Specifications HD2200M

| Max Turning Dia [mm] | 300 |

| Max Turning Length [mm] | 467 |

| Driving Method | Belt |

| Chuck Size [inch/mm] | 8″/203,2 |

| Spindle RPM [rot/min] | 4,500 |

| Spindle Output [kW] | 18.5/15 |

| Spindle Torque [Nm] | 206/125.3 |

| Travel (X,Y) [mm] | 215/482 |

| Rapid Travel [m/min] | 24/30 |

| Slide Type | BOX |

| No. of Tools | 12 |

| Tool Size (turning/milling) [mm] | 25/40 |

Technical Specifications HD2200MC

| Max Turning Dia [mm] | 300 |

| Max Turning Length [mm] | 452 |

| Driving Method | Belt |

| Chuck Size [inch/mm] | 10″/254 |

| Spindle RPM [rot/min] | 3,500 |

| Spindle Output [kW] | 18.5/15 |

| Spindle Torque [Nm] | 403.6/245.4 |

| Travel (X,Y) [mm] | 215/482 |

| Rapid Travel [m/min] | 24/30 |

| Slide Type | BOX |

| No. of Tools | 12 |

| Tool Size (turning/milling) [mm] | 25/40 |