LM1600TTS | LM1600TTMS | LM1600TTSY

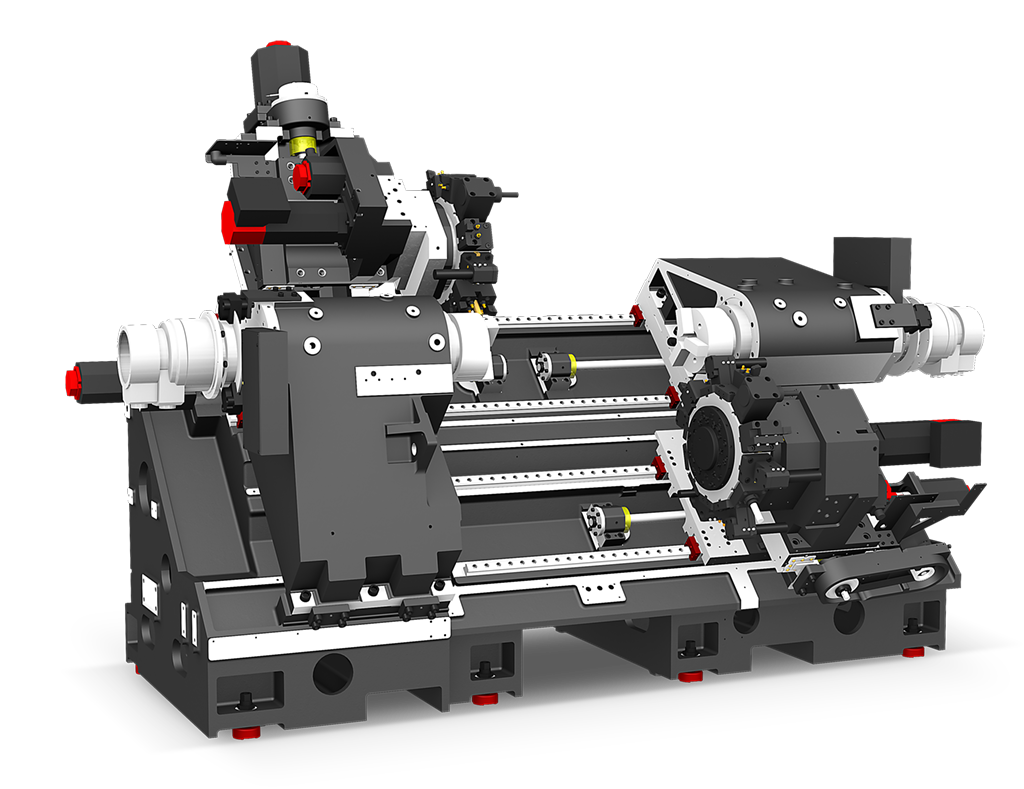

The LM1600TT turning center with two universals and two turns is a productive multifunctional lathe that has high rigidity and precision in CNC cutting.

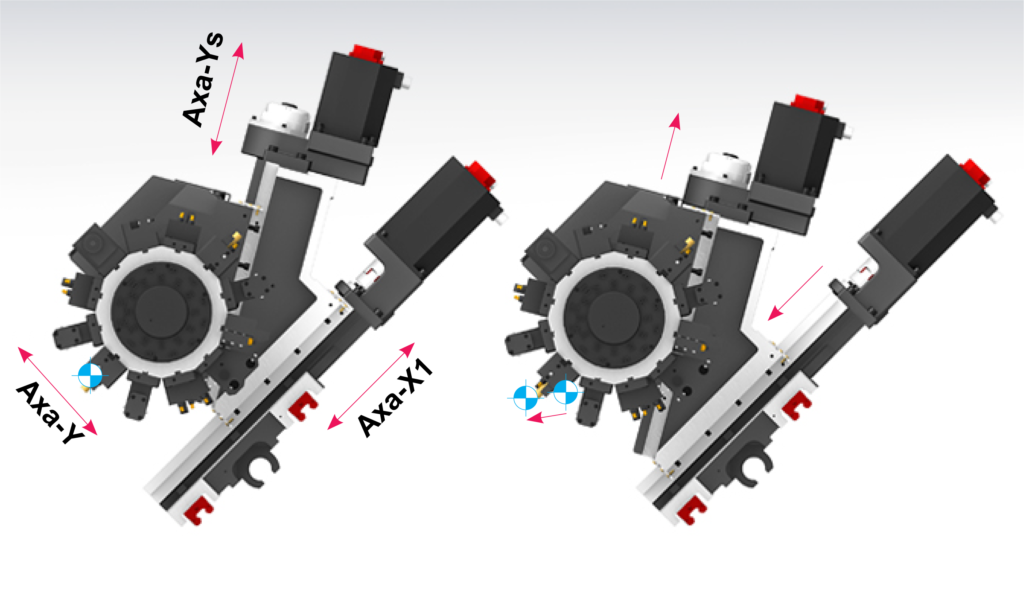

The LM-TT series demonstrates the technological capability of Hyundai-WIA by machining any type of complex parts with two universals, two towers and the Y axis.

- Large output built-In spindle motor

- High productivity guaranteed with simultaneous utilization of upper and lower turrets

- Robust BMT turret

- Multitasking is possible with the addition of Y axis to the upper turret (TTSY specifications)

- Integrated processing through synchronized control of Main and Sub Spindle

- Design of the hybrid slideway, combining box guideway(X/Y-axis) and roller guideway(Z-axis) (LM1600/1800TT Series)

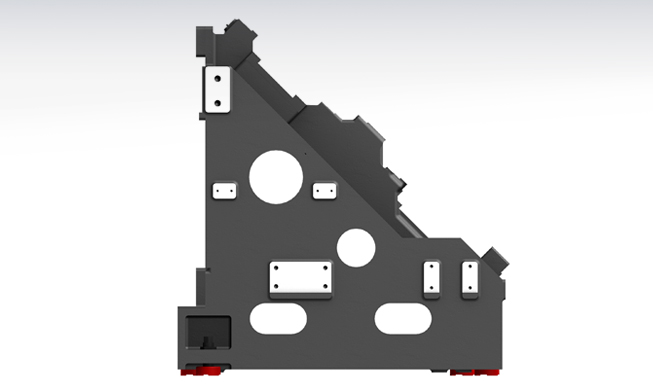

High Precision, High Rigidity Bed Structure

The LM1600/1800TT Series features a one-piece 45° slant bed design based on FEM analysis to provide improvement in vibration absorption and thermal displacement. This unique design ensures stable and precise processing.

Guideway

Hybrid Slideway

Each axis on the LM1600TT/1800TT Series is designed with slideways that optimize the characteristics of the axes. For the X/Y-axis, box guideways are used to endure heavy load. For the Z-axis, roller type LM guideways are used to optimize feed capability.

Ball Screw

In order to eliminate thermal growth and increase accuracy, all axes are

driven by high precision double anchored ballscrews.

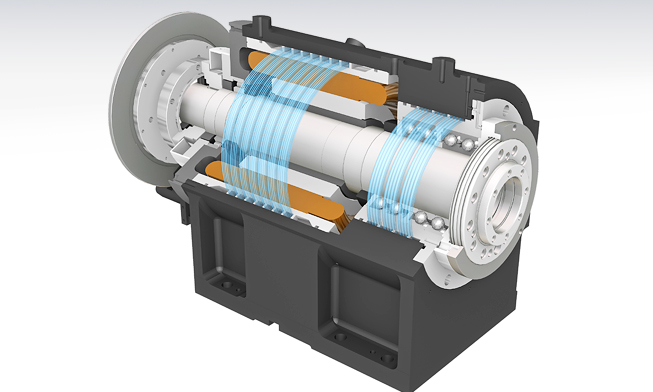

Built-in Spindle

Shaft specializing in fast and hard cutting and milling operations

LM-TT Series main/sub spindle are built-in, thereby minimizing noise and vibration even during high speed operations. The built-in spindle is capable of rapid acc/ deceleration and stable heavy duty cutting.

C-Axis Control

LM-TT models featuring milling are equipped with full C-axis(0.001°) capability on both spindles.

Sub Spindle

Machines with a sub spindle can perform secondary operations with a single setup, increasing flexibility and productivity.

Spindle Oil Cooling

The LM-TT Series features a spindle cooling system on both main/sub spindles as standard. This system minimizes thermal growth during operations and helps to maintain stable machining environment.

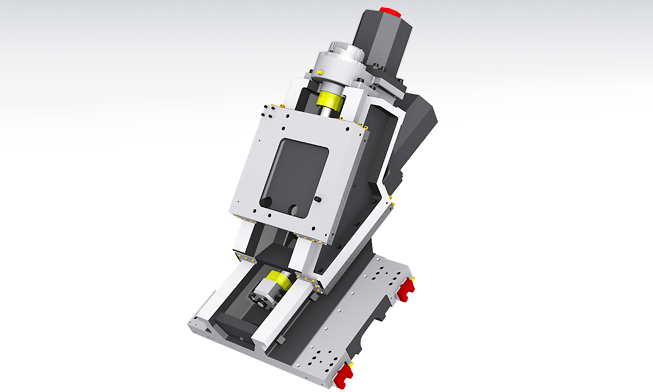

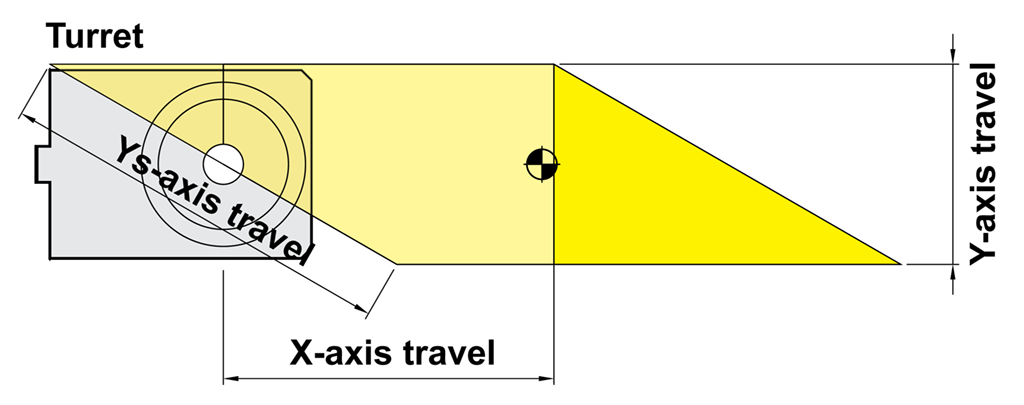

Wedge Type Y-Axis Structure

The LM-TT Series is designed with a wedge type Y-axis that is

transferred by the simultaneous operation of the Ys-axis and the

X-axis. In addtion, excellent rigidity makes it possible to perform superb quality when machining a heavy-duty cutting.

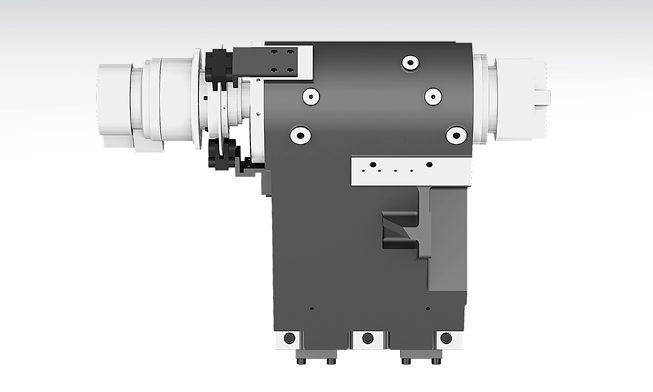

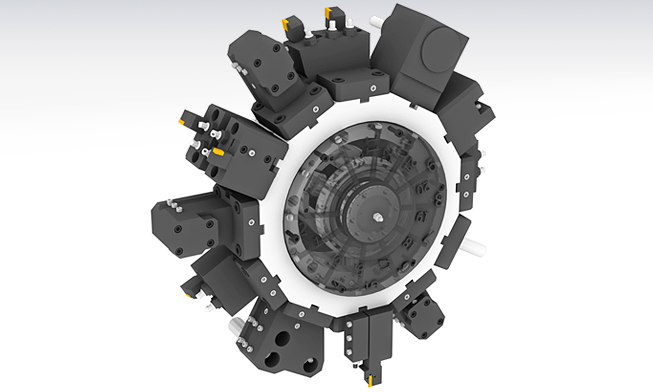

Turret

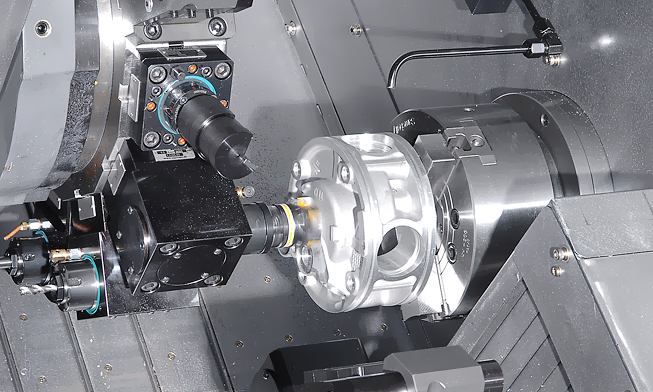

Mill Turret

The upper and the lower turrets are equipped with powerful

servo motors, which guarantee high productivity and precision. In particular, a total of 24 (Option 48) tools can be installed on both turrets, and high speed precision machining of complex products is possible with a single setup.

Mill Tool Holder

Machining capability has increased with the addition of straight milling head tool holder, which can machine workpieces from the side, and angular milling head tool holder, which can perform I.D. operations.

Portscule Speciale

With the Y-axis, the LM-TT series can process high value-added products using a variety of rotating tools. In particular, there is a multi-holder for attaching a variety of tools to one holder, and an eccentric rotary tool for handling eccentric parts without additional axis travel, which can realize integration of process with one machine.

LM1600TT turning center with high precision in machining

Automatic Q-Setter

Cutting tools are calibrated quickly and accurately with the addition of a q-setter. Each tool tip is touched off manually using a sensor that inputs the position automatically.

Linear Scale

Linear scales increase positioning accuracy and reduce distortion caused by thermal growth, thus ensuring a more accurate finished part. (LM1600/1800 Series).

Work Probe

Workpiece coordinate values can be set automatically using the optional spindle probe.

Technical Specifications LM1600TTS

| Max Turning Dia [mm] | 230 |

| Max Turning Length [mm] | 705 |

| Driving Method | Built in |

| Chuck Size [inch/mm] | 6″/152,4 6″/152,4 |

| Spindle RPM [rot/min] | 6,000 |

| Spindle Output [kW] | 15/11 |

| Spindle Torque [Nm] | 208/140 |

| Travel (X1/X2/Z1/Z2) [mm] | 165/195/700/720/700 |

| Travel (X1/X2/Z1/Z2/ZB) [mm] | – |

| Rapid Travel (X1/X2/Z1/Z2) [m/min] | 20/20/40/40/40 |

| Rapid Travel (X1/X2/Z1/Z2/ZB) [m/min] | – |

| Slide Type | LM |

| No. of Tools | 2 x 12 |

| Tool Size (turning/milling) [mm] | 20/32 |

| Milling Tool Speed [rot/min] | – |

Technical Specifications LM1600TTMS

| Max Turning Dia [mm] | 230 |

| Max Turning Length [mm] | 705 |

| Driving Method | Built in |

| Chuck Size [inch/mm] | 6″/152,4 6″/152,4 |

| Spindle RPM [rot/min] | 5,000 |

| Spindle Output [kW] | 15/11 |

| Spindle Torque [Nm] | 208/140 |

| Travel (X1/X2/Z1/Z2) [mm] | 165/195/700/720/700 |

| Travel (X1/X2/Z1/Z2/ZB) [mm] | – |

| Rapid Travel (X1/X2/Z1/Z2) [m/min] | 20/20/40/40/40 |

| Rapid Travel (X1/X2/Z1/Z2/ZB) [m/min] | – |

| Slide Type | LM |

| No. of Tools | 2 x 12 |

| Tool Size (turning/milling) [mm] | 20/32 |

| Milling Tool Speed [rot/min] | 5,000 |

Technical Specifications LM1600TTSY

| Max Turning Dia [mm] | 230 |

| Max Turning Length [mm] | 705 |

| Driving Method | Built in |

| Chuck Size [inch/mm] | 6″/152,4 6″/152,4 |

| Spindle RPM [rot/min] | 5,000 |

| Spindle Output [kW] | 15/11 |

| Spindle Torque [Nm] | 208/140 |

| Travel (X1/X2/Z1/Z2) [mm] | – |

| Travel (X1/X2/Z1/Z2/ZB) [mm] | 165/195/700/720/700/100 |

| Rapid Travel (X1/X2/Z1/Z2) [m/min] | – |

| Rapid Travel (X1/X2/Z1/Z2/ZB) [m/min] | 20/20/40/40/40/7.5 |

| Slide Type | LM |

| No. of Tools | 2 x 12 |

| Tool Size (turning/milling) [mm] | 20/32 |

| Milling Tool Speed [rot/min] | 5,000 |