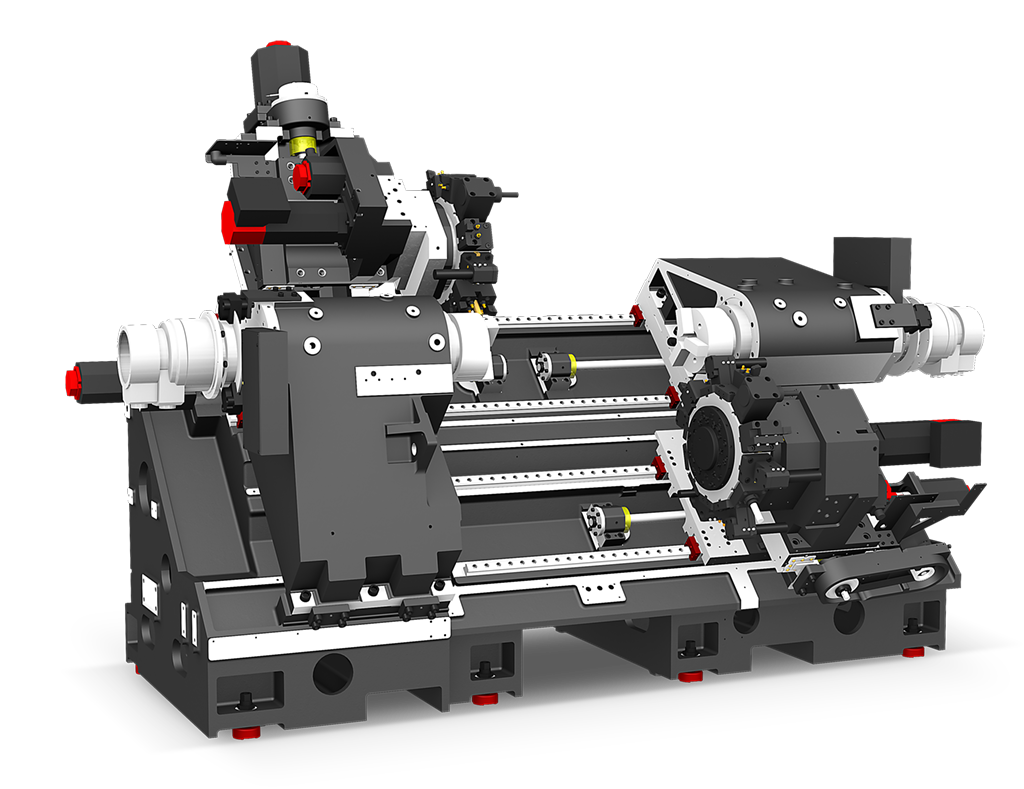

LM2500TTSY II

The turning center LM2500TTSY II Twin Spindle & Turret Multitasking CNC Turning Center is a productive multifunctional lathe that has high rigidity and precision in CNC cutting.

- Twin spindle and twin turret for multiflexibility

- Improved spindle power for heavy duty cutting (Max.torque : 724N.m)

- Improved Mill Turret Machining Capability (Max.torque : 70N.m)

- Increased Spindle Rod Machining Diameter

- Box guideways on all axes for heavy duty cutting

- Wedge Type Y-Axis Structure

LM2500TTMS/TTSY Turning Center demonstrates Hyundai-WIA’s technological capability by machining any type of complex parts with two universals, two turrets and the Y axis.

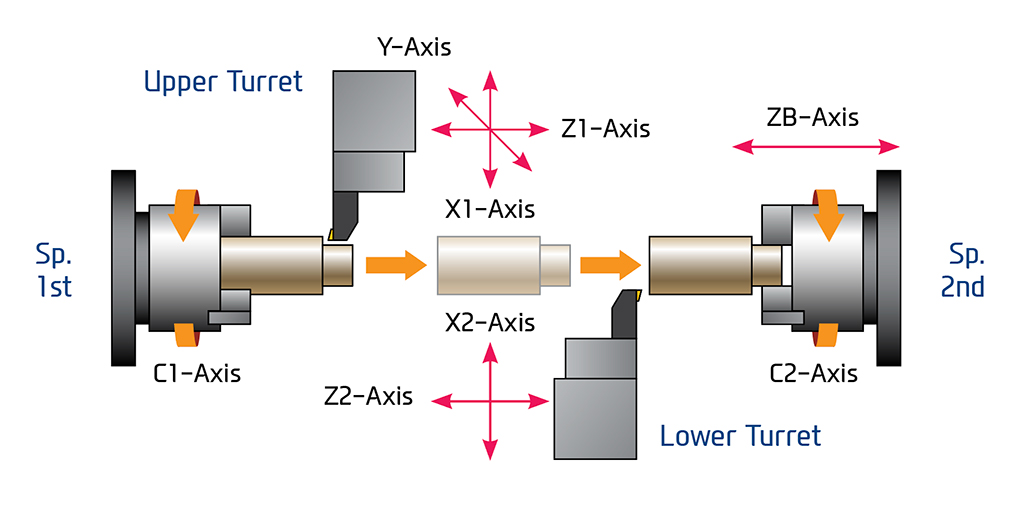

Multitasking Structure

Rear Machining

Upon completion of the external operation, the left spindle rotates at the same rate as the right spindle and the workpiece is handed over to the left spindle. Once the workpiece is secured in the left spindle rear processing is possible.

First and second operations can be performed with a single setup.

Two different operations are possible to machine simultaneously on two spindles.

Multitasking (Turning, Milling Y-Axis Machining)

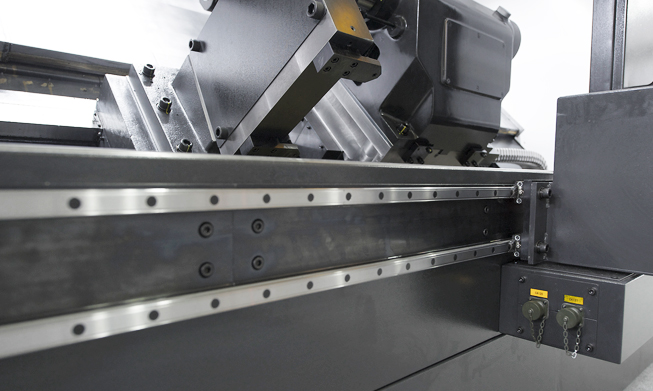

All Axis Box Guideway

Box Guideway

All axes on the LM2500TTSY II is designed with Box Guideways to provide rigidity and accuracy even during heavy duty operations.

High Performance Ball Screw

World-class ball screws were applied in LM2500TTSY II for accurate positioning, minimization of thermal displacement, and reinforced durability. The ball screw deformity was especially minimized by applying high- precision pre-load to the bearings placed in multiple rows at both ends of the ball screws.

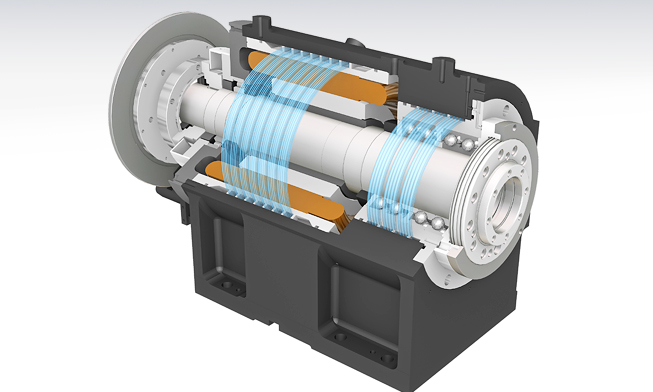

Right & Left Built-in Spindle

Built-in Spindle

The right and left spindles with a built-in motor structure can minimize the vibration and heat generated during high-speed rotation, which makes them ideal for high-precision machining. Also, the spindle chiller, installed to minimize thermal displacement of the right and left spindles, ensures the quality of products despite long machining process.

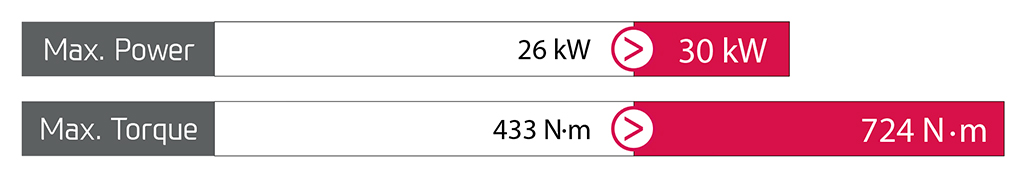

Improved Spindle Power for Heavy Duty Cutting Machining

The heavy duty machining capability has been improved significantly with the maximum output increased by 15% and the maximum torque increased by 67% compared to the previous model.

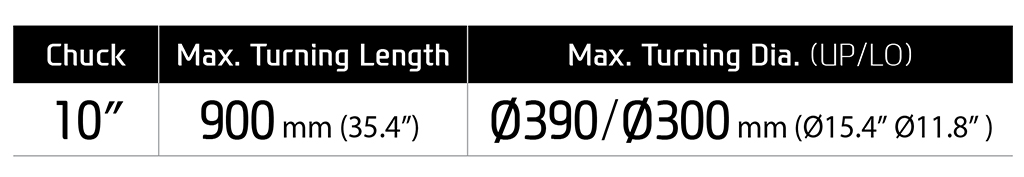

Increased Spindle Rod Machining Diameter

The rod machining diameter has been increased from Ø76 to Ø81 to expand the rod machining area.

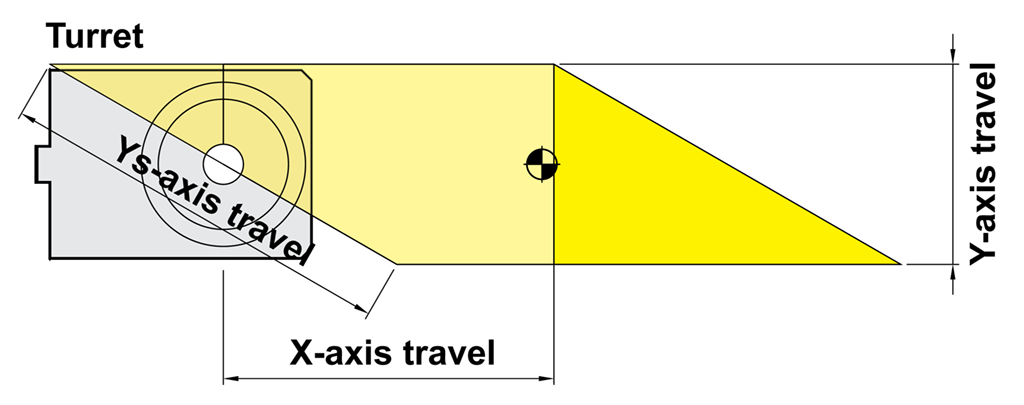

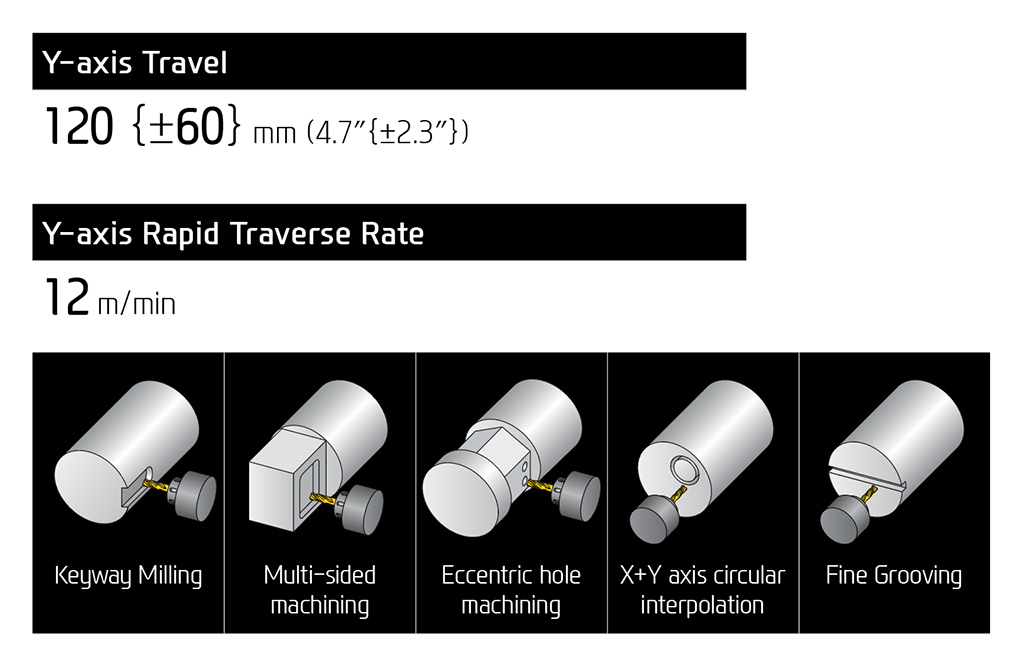

Y-Axis Function

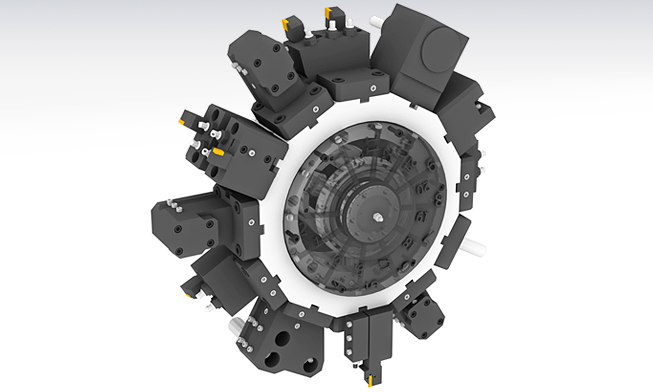

12 tools(std.) / 24 tools(opt.) → Various types of machining available

Wedge Type Y-Axis Structure

The wedge type Y-axis structure offers superior rigidity and it can maintain stable machining precision even for heavy duty machining. The Y-axis structure especially allows machining at a location away from the center, which allows almost all machining to be performed by a single machine, without secondary machining using a

separate machining center.

Upper/Lower Twin Turrets

Twin Mill Turrets

The upper and the lower turrets are equipped with powerful servo motors, which guarantee high productivity and precision. In particular, a total of 48 tools can be installed on both turrets, and high speed precision machining of complex products is possible with a single setup.

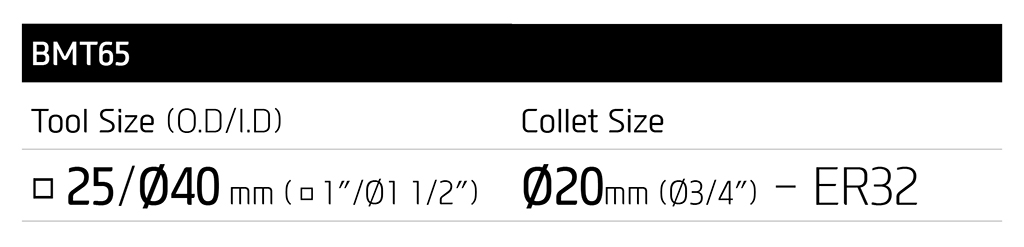

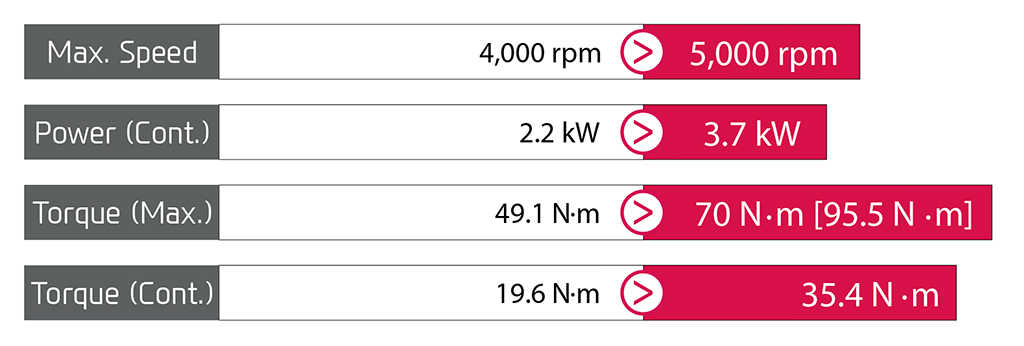

Improved Mill Turret Machining Capability

The continuous output, maximum rpm, and torque were improved significantly compared to the previous model.

LM2500TTSY II High Precision System

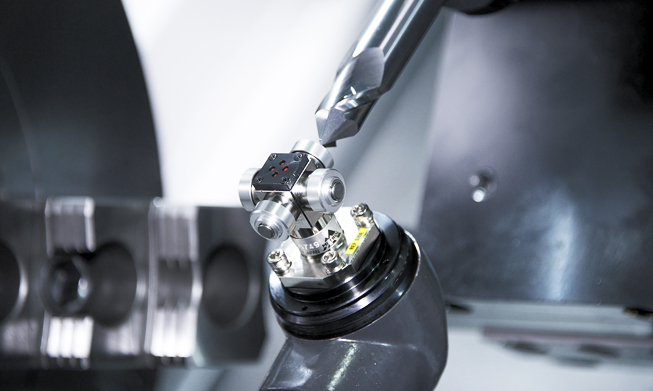

Automatic Q-Setter

Cutting tools are calibrated quickly and accurately with the addition of a q-setter. Each tool tip is touched off manually using a sensor that inputs the position automatically.

Linear Scale

Linear scales increase positioning accuracy and reduce distortion caused by thermal growth, thus ensuring a more accurate finished part.

Touch Sensor

Workpiece coordinate values can be set automatically using the optional spindle probe.

Technical Specifications LM2500TTSY II

| Max Turning Dia [mm] | 390 |

| Max Turning Length [mm] | 900 |

| Driving Method | Built in |

| Chuck Size [inch/mm] | Main 10″/254 Sub 10″/254 |

| Spindle RPM [rot/min] | 4,000 |

| Spindle Output [kW] | 30/22 |

| Spindle Torque [Nm] | 724/410 |

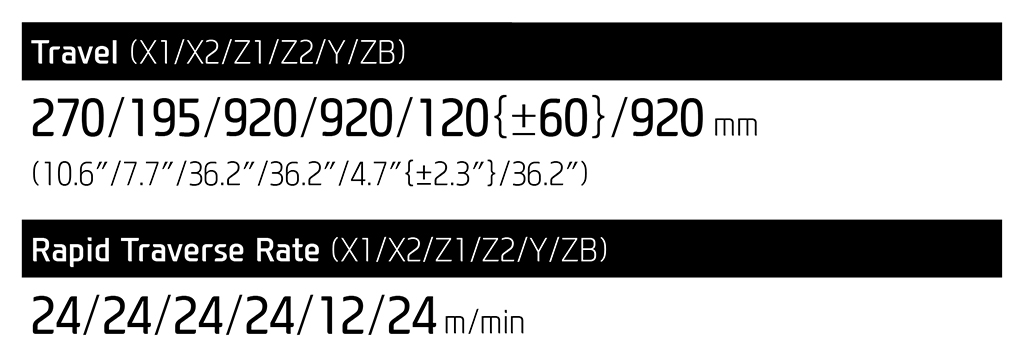

| Travel (X1/X2/Z1/Z2/ZB) [mm] | – |

| Travel (X1/X2/Z1/Z2/ZB/Y) [mm] | 270/195/920/920/920/120 |

| Rapid Travel (X1/X2/Z1/Z2/ZB) [m/min] | – |

| Rapid Travel (X1/X2/Z1/Z2/ZB/Y) [m/min] | 24/24/24/24/24/12 |

| Slide Type | BOX |

| No. of Tools | 2 x 12 |

| Tool Size (turning/milling) [mm] | 25/50 |

| Milling Tool Speed [rot/min] | 5,000 |